Alternatives for Developing Supply Chain Simulation Capabilities

Today I would like to talk about a non-essential, but helpful part of supply chain management: Simulation.

Simulation can be used in a supply chain setting on many different levels. On a strategic level there are models to analyze scenarios for the optimal locations of one’s factory, on a tactical level inventory management and distribution policies are treated and on the operations side route-optimization is a generally used. Of course there are also non-simulation models for these tasks, but this article is not about the pros and cons of that.

The goal of this article is to give you an overview what general differences exist between the approaches to build a non-specialized capability for supply chain simulation.

Approaches for building simulation capabilities

Simulation tools can be categorized into the following scheme.

- Data driven simulators, can be defined as a simulation model which can be parameterized by providing data (e.g. by using spreadsheets), it’s purpose is to model a specified set of systems.

- Pros: Usually easy to configure for the user

- Cons: Less flexibility, since the simulator can only interpret parameters which its programming allow; standard graphical representation, which fits for the set of systems may not be optimal for one special case.

- Interactive simulator, builds on modules for supply chain elements. Those have to be arranged and parameterized by the user.

- Pros: due to the modularity the visual representation can come very close to the real supply chain

- The sub-model approach, is comparable to the module approach, but instead of providing closed modules, models for a sub-system are used.

- Pros: The user can better specify the level of detail he needs and also have differing levels of detail for different supply chain tiers.

- Cons: Increased requirements for the abilities of the user

Furthermore there are:

- Simulator extensions, are extensions written for a general purpose simulation software, which enhance the capabilities to model a specific set of systems.

- Object class libraries, are an even lower level where objects are predefined, but not bundled with a simulator, but built on a general programming language.

Comparison and trade-offs

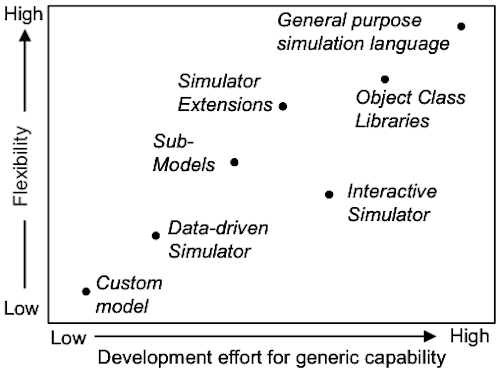

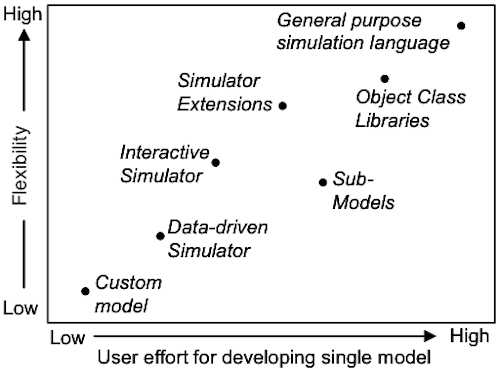

After defining the different approaches the author then compares the different approaches (see figure 1 and 2).

There is no golden rule of choosing the right approach for building simulation capabilities, but there are some important criteria and trade-offs to select the best approach.

Figure 1 focusses on the development of a generic simulation capability, which could be used to simulate a wider range of problems. If the objective is to develop only one model for a specific purpose (figure 2) the major difference is, that the effort for using sub-models is there higher than using the interactive simulator, since the learning curve for the former is steeper.

Jain names the following criteria, which should be used to decide on the correct approach:

- Effort for developing simulation model instance vs. effort for developing a generic simulation capability

- Flexibility of the acquired knowledge

- Base software to be used

- Role of the user in the simulation process

- Animation capabilities of the selected product

- Utilization of standards (by the simulation software), e.g. in data import / export, model format

- Maintenance efforts needed for the capability

- Execution time of the simulator

Conclusion

I think Jain could have made a better job to make the difference clear between the decision which software tool to acquire and which capabilities are needed at a company.

These decisions are of course interrelated, but since especially for a larger company it may be also an option to buy capabilities externally or by employing specialists.

For a complete framework the goal orientation was missing as well. For me the first step in such a process would be to define the company’s goals which then lead to the needed capabilities.

But, the reason why I presented this article is that I still think it contains some good classifications to select a fitting approach for creating simulation capabilities.

Jain, S. (2008). Tradeoffs in building a Generic Supply Chain Simulation Capability Proceedings of the 2008 Winter Simulation Conference, 1873-1881

Add new comment