Decision Support for Supply Chain, Product and Process Design

Many companies are struggling with the idea to use modern optimization techniques to support decision making in strategic supply chain management.

But beside mathematical modeling of the supply chain there are other methods as well, such as network based approaches. In their 2005 paper Blackhurst, Wu and O’Grady present a more intuitive decision support method with the goal to improve decisions within the supply chain context.

Methodology

Case Study

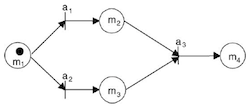

As an example Blackhurst et al. use a case study, where they model the chassis assembly of Rockwell Collins, using actual data of their processes. The result of the status quo can be seen in figure 2. The network presentation is enhanced by the added information, like the lead time (LT) and the reorder point (ROP) at the nodes.With the help of these networks the authors then optimize the network from the base case with local informations first to an information sharing network. This already helps reducing echelon inventory a lot. The second adjustment is to change raw materials to improve the product and the network even further.

Conclusion

The presented method for improving the supply chain network is intuitive, easy to understand and implement. Yet, it does not seem to be so new, nevertheless, it is a nice addition to the usual supply chain networks to add some key indicators directly at the nodes.

Even though this tool might seem overly simplistic, I really recommend using more tools like these. Many companies do not even analyze their network on a systematic basis, so this looks to be a good starting point for companies which have not used similar tools before.

Blackhurst, J., Wu, T., & O’Grady, P. (2005). PCDM: A Decision Support Modeling Methodology for Supply Chain, Product and Process Design Decisions Journal of Operations Management, 23 (3-4), 325-343 DOI: 10.1016/j.jom.2004.05.009

Add new comment