Enablers and Barriers to Risk Mitigation

Everybody concerned with the task of developing risk mitigation strategies has a list in his mind of different factors influencing a company’s exposure to risk and if you think about it: those factors are probably related.

Example: The number of suppliers for one component can have a huge impact on risk, but the necessity of a high number of (redundant) suppliers may itself be affected by the trust you built with your main supplier. Both trust and having multiple suppliers affect supply chain risk by themselves, but they are also related.

Faisal et al (2006) investigate these relations in a more in depth way.

Results

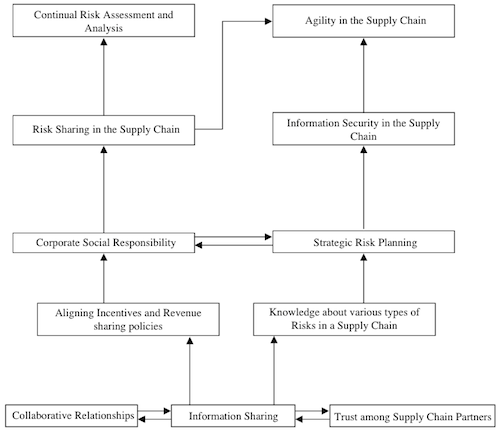

Their results are summarized in figure 1. Information sharing has the most driving capabilities and is therefore located on the bottom of the pyramid. Aligning incentives within the supply chain also drives SC risks but is itself dependent on the information sharing within the supply chain, and so on.

Methodology

The authors used Interpretive Structural Modeling to come to these results. The goal is to transform a plain list of variables which are affecting a system into a hierarchy.

Steps:

- Generate the relevant factors (eg. using brain storming technique)

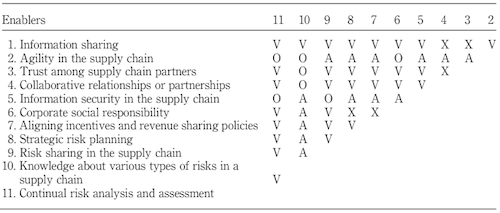

- Transform the list into a matrix and mark dependencies using expert opinion (see figure 2)

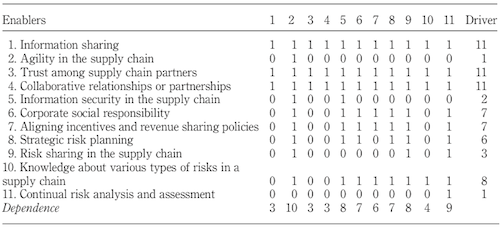

- Extend the matrix and calculate driving capabilities and dependence (last row / line, see figure 3)

- Using these results build the model

Conclusion / Critique

This model shows several important points: some factors are supposed to be drivers of risk mitigation, therefore influencing them will have a much wider positive effect then only locally. Risk managers should thus focus their time and money on these factors!

The method used has also its drawbacks. First, The results presented by Faisal et al. (2006) are aimed on a very high abstraction level, starting with the initial list, which is the foundation of the whole hierarchy. Since there is no iteration process to enhance this initial list again, it is of utmost importance to be very sure about it. Second, there are also no recursive relations between variable, for example one could think that agility in the supply chain (high dependence index) might influence the trust among the supply chain partners (very high driving index) due to a more customer oriented performance. Third, the resulting list is heavily dependent on the expert opinion, which transforms the variable listing into the dependence matrix.

Those caveats have to be considered before using the resulting hierarchy; for most practitioners looking for such a listing, the best way to proceed would be to recreate it with variables specific to the context of the company.

Faisal, M. N., Banwet, D.K., & Shankar, R. (2006). Supply Chain Risk Mitigation:

Modeling the Enablers Business Process Management Journal, 12 (4), 535-552

Add new comment