Knowledge-based Supply Chain Risk Management

I just recently had a discussion with a professor at Mahidol University (Bangkok), where I was staying for a research exchange, on how knowledge can be used to mitigate risks within a supply chain. If you search here on the blog for “knowledge” there are already several articles covering parts of how knowledge can be used as a strategy (Internet Induced Risks for global Supply Chains) or the benefits of information sharing (Information Sharing in Supply Chains).

But there is no review on a common framework which contains all / many aspects of the use of knowledge in SCRM. So I looked in my personal library and found the following article, which presents a comprehensive framework for SCRM based on knowledge.

Key aspects in knowledge based SCRM

The author sees several key elements to improve SCRM by using available knowledge within the chain.

- Usage and sharing of the knowledge about supply chain risks: In supply chain risk management it is necessary not only to know about the company’s own risks but also include the knowledge about the risks of other supply chain participants

- This knowledge sharing should be supported by information technology.

- A dynamic knowledge alliance should build the organizational foundation, members are dynamically selected due to their importance in the chain

- Positive effects of the knowledge based SCRM do not come instantly so, long term cooperation will be needed

Framework

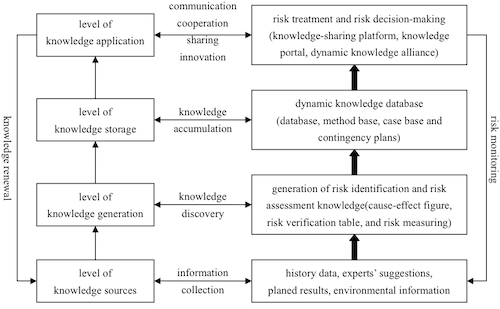

The author developed the following framework (figure 1), which contains every aspect form identification and assessment of the sources of risk knowledge, the knowledge generation, storage and application.

The author recommends to base the implementation on a) the accumulation of risk knowledge, emphasizing the importance of building the database and filling it with relevant data and furthermore b) developing a dynamic knowledge alliance. Primarily this alliance also signifies an organizational shift towards a more open exchange between companies, for this processes for risk gathering, storage, etc. have to be standardized across companies.

Conclusion

I present this framework as food for thought primarily from a business perspective. I really liked some of the ideas and conclusions, nonetheless I have to point out some scientific flaws that make me wonder how the paper could be published in a journal.

- The paper is much too short; up to now I was under the impression that I had a very brief writing style, but 6 pages are just not even enough to define all the different terms the author used.

- The shortness is also reflected in the missing arguments, there is no discussion of either current literature nor other results

- The author did not mention any method which he used as a foundation for his findings. So I have to assume that he just thought it up by himself. This actually does count as scientific evidence as well, but it’s very low on the validity scale. This is also the reason why I still would suggest it as a discussion base for a business setting, but I would definitely not start redesigning my organization according to the views mentioned in the paper

- There is no discussion of the terms knowledge versus information and as far as I understand these terms he might actually be talking about information management here.

- I was happy to see some hints on the implementation, nonetheless there is also no discussion of how the tacit knowledge can be included into this information sharing framework.

But still, I liked the idea of the dynamic knowledge sharing organization, as a virtual frame where companies share information on risk management. Because that’s for sure, not many companies are sharing enough information on the supply chain risks they see.

The full article can be downloaded here.

Guo, Y. (2011). Research on Knowledge-Oriented Supply Chain Risk Management System Model Journal of Management and Strategy, 2 (2), 72-77

Add new comment