Let me help you with... Time-Based Risk Management

Today I present you only one chapter of a great book by Wu and Blackhurst: “Managing Supply Chain Risk and Vulnerability” (which can be bought on amazon.com here).

I especially like the third chapter by Professors Sodhi and Tang on a new approach to managing disruptions: Time-based Risk Management.

The whole book features a more practitioner oriented approach so don’t expect too much focus on the methodological parts.

Reason for risk management

Supply chain disruptions should have arrived at the board rooms due to

- “short-term effects (negative publicity, low consumer confidence, market share loss, etc.) and

- long-term effects (stock prices and equity risk).”

So there should be enough drive to pay for even some of the more expensive risk management initiatives. Nonetheless a really robust supply chain strategy has to mitigate supply chain risks and increase profits at the same time.

Time-based risk management

The time-based risk management approach aims to travel on this thin line and deliver a strategy to mitigate disruption risk without compromising profits.

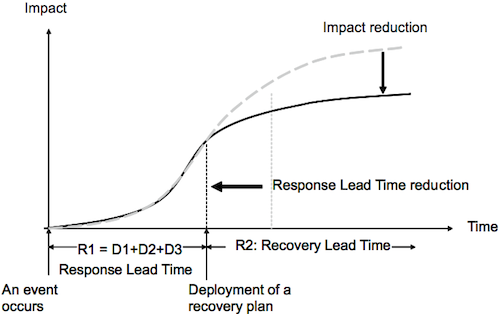

It consists of three time frames which should be in focus of the risk manager:

- time to detect a disruption (D1),

- time to design a solution (D2),

- time to deploy (D3),

- time to response is set to the sum of D1 to D3 (R1), and

- time to recover (R2)

The authors argue, that prior work has pretty much focussed on the generation and selection of recovery plans, but only after the event has occurred.

The time-based risk management now tries to reduce the time needed for the other elements, since “just as 80% of the total cost of a product is determined during the product design phase, the activities that take place for designing response can have significant effect on the overall impact of a disruption.”

Argumentation

Furthermore, based on three case studies (e.g. the Nokia / Ericsson Case) the authors argue that a longer response time can also lead to hugely increased recovery times. “This is mainly because the magnitude of the problem triggered by the event escalated exponential over time.”

This argument is illustrated in figure 1 using a exponential epidemic model.

Activities to reduce response time

The authors name five time-based disruption management strategies to reduce the response time (R1) and therefore also the recovery time (R2).

- Work with suppliers and customers to map risks

- Define roles and responsibilities

- Develop monitoring/advance warning systems for detection

- Design recovery plans

- Develop scenario plans and conduct stress tests

Risk and reward

As argued in the beginning robust strategies should not only support the company during times of disruption, but also increase competitiveness.

Using the case of Zara (fashion industry) the authors outline the advantages of time-based risk management. By managing their design, manufacture and deliver operations very closely and centralized with a already very low lead time Zara can detect disruptions almost in real time (low D1). New clothes and therefore a market adaptation can be designed very quickly, so D2 is quite low as well. Since suppliers and distribution are usually in close proximity to the factories deployment of new strategies is fast as well (low D3).

However these low lead times have not (primarily) been established for risk management purposes, but they are part of Zara’s business strategy and help them achieving continuous high growth rates as well.

Conclusion

Sodhi and Tang use very illustrative cases to make their points for a time-based risk management approach. This approach represents a corporate strategy which of course has to include a very broad definition of supply chain management. So not only the logistics and manufacturing parts are included, but also product design, finance, …

Sodhi, M.S., & Tang, C.S. (2009). Managing Supply Chain Disruptions via Time-Based Risk Management Managing Supply Chain Risk and Vulnerability: Tools and Methods for Supply Chain Decision Makers., 29-40

Comments

Thankyou, I am writing an assignment on Supply chain strategies and was reading Professors Sodhi and Tang's book. This helps me understand it better

Add new comment