Managing Supply Chain Disruptions in the Chemical Industry

This is already my second article (click here for the first) about managing supply chain risks in the chemical industry. This time by Paul R. Kleindorfer and Germaine H. Saad from Wharton and the Widener University. But this industry is quite interesting since it has to withstand a multitude of risks, so let’s get right to business:

Goal

As the title indicates: the authors focus on risks from disruptions to normal activities and not the omnipresent risk of coordinating supply and demand.

The authors aim to achieve three goals:

- Development of a conceptual framework for risk assessment and mitigation

- Analyze accident history from the six years between 1995 and 2000

- Derive implications for the design of management systems to cope with supply chain disruptions

Literature analysis

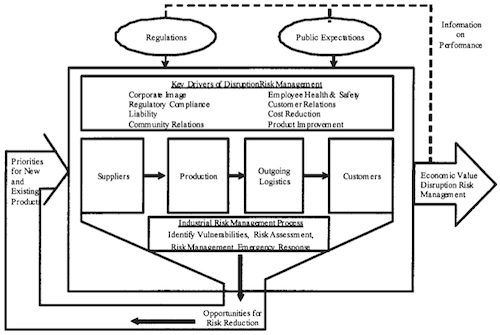

The authors use the SAM method, where the goal is first to analyze the risk S ources, then A ssess the risks and find the right M itigation strategies.

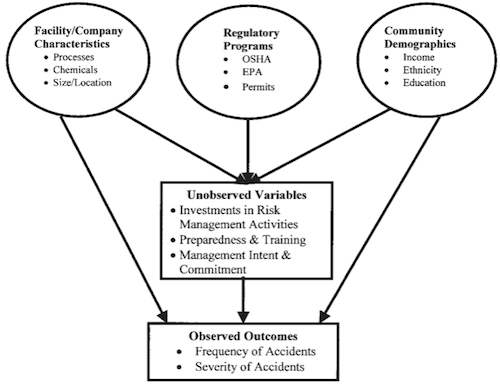

The authors first investigate the SAM process using literature analysis and conclude with the process depicted in figure 1 and a four step process to manage disruption risks:

- “Obtain senior management understanding and approval, and set up organizational responsibilities for managing the Disruption Risk Management process.”

- “Identify key processes that are likely to be affected by disruptions and characterize the facilities, assets, and human populations that may be affected.”

- “Traditional risk management is then undertaken for each key process to identify vulnerabilities, triggers for these vulnerabilities, likelihood of occurrence, and mitigation and risk transfer activities.”

- “Reporting, periodic auditing, management, and legal reviews of implementation plans and on-going results (e.g., of near-miss management and other disruption risks) complete the business process for disruption risk management.”

Case study chemical industry

The further analysis of disruption risk management is done using a case study approach. The authors used a database with access to accident activities in the chemical industry during the time between 1995 and 2000. Sources were natural hazards, equipment or human failure and sabotage.

The framework depicted in figure 2 was used as a basis for the analysis.

Results

Kleindorfer and Saad conclude that, “two key dimensions emerge as fundamental in guiding management practice of disruption risk in supply chains:”

The first dimension consists of strategies and actions aiming at reducing the frequency and severity of risks faced, at both the firm level and across the supply chain. The second element focuses on increasing the capacity of supply chain participants (whether a separate firm or a subsidiary facility) to sustain/absorb more risk, without serious negative impacts, or major operational disruptions.

Furthermore in the chemical industry special care has to be taken to include the stakeholders, like regulators or the employees in mitigation activities.

Lastly, the authors state two conditions which have to be met to ensure effective implementation of risk management measures:

Condition C1. The approaches used to mitigate disruption risks must “fit” the characteristics and needs of the underlying decision environment. Different supply chain environments will give rise to different approaches to assessment and mitigation. Even within a given sector such as mass retailers with global supply chains, the approaches taken by different companies will be different, given their differences in corporate culture and their methods of managing their supply chains. In the business of disruption risk management, one size will definitely not fit all.

Condition C2. Trust, information and continuing profitability are the basic glue that makes supply chain partnerships a reality. Continuous coordination, cooperation, and collaboration among supply chain partners are needed for risk avoidance, reduction, and mitigation such that the value and benefits generated are maximized and shared fairly. Different contractual and incentive schemes are now emerging as practical means toward this end. Linking risk assessment and risk management to identify vulnerabilities and opportunities for cost-effective mitigation is the first step in providing a rational basis for individual and group action among supply chain partners. Random investments or shots in the dark that do not properly account for the interdependencies across the supply chain will ultimately waste resources and destroy trust.

Conclusion

The authors already admit that the data used for their case study is based on a facility level. These facilities are of course part of the supply chain, but one can pose the question if the results are really relevant for supply chain risk management.

Moreover, one has to differentiate between supply chain security and supply chain disruptions. At least from my practical experience especially in the chemical industry facility security has played a major role since many decades and is deeply rooted in the companies themselves. Supply chain risk management on the other hand is a new approach and very much separated from it. So for a paper on exactly this topic I am missing a discussion of the question how these aspects should be integrated.

Kleindorfer, P.R., & Saad, G.H. (2005). Managing Disruption Risks in Supply Chains Production and Operations Management, 14 (1), 53-68

Comments

I really love your blog.. Pleasant colors & theme. Did you create this web site yourself?

Please reply back as I'm hoping to create my own site and would love to

know where you got this from or what the theme is named.

Kudos!

What's your current site? The site is based on the Drupal CMS the theme is mostly my own handiwork (together with a friend of mine).

Daniel

Add new comment