Mitigation or Contingency Strategies against Disruptions

Uncertainty can be categorized in continuous risk, more slowly changing patterns, and disruptions, which describe abrupt changes in a system.

Tomlin (2006) investigates the question which supply chain strategies perform best when dealing with the later.

Mitigation vs. Contingency Planning

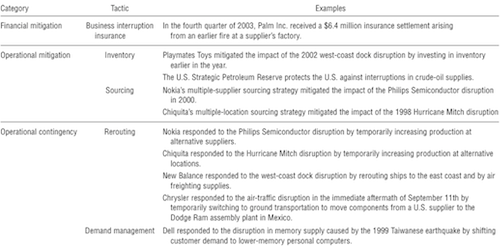

From case studies analyzed in literature the author first deducts disruption management strategies used in practices. The summary can be seen in figure 1.

Mitigation strategies are distinguished from contingency strategies by the time when an action is performed. Often most of the cost occur at the same time.

Mitigation Strategies, are planned and executed before the risk occurs (eg. increasing inventory levels).

Contingency Strategies, are planned beforehand but executed after the risk occurs (eg. power generator after a power failure).

Optimal Strategies

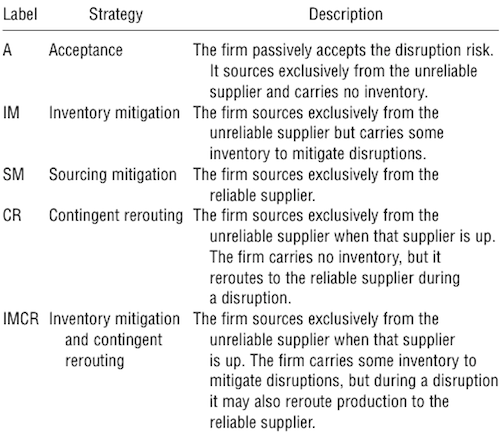

Figure 2 finally summarizes the strategies which are tested in Tomlin’s model.

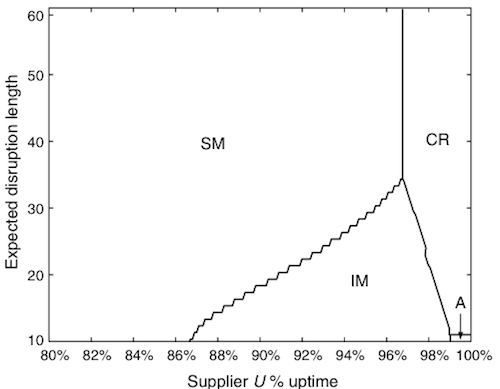

To test the strategies the author develops a mathematical model. The model shows that Supplier uptime [%] and the expected disruption length have a major impact on the chosen strategy. Figure 3 therefore shows optimal strategies depending on those parameters. The results vary for different flexibility levels.

From the data at hand Tomlin draws the following conclusions:

- Switching to a more reliable source is favored over inventory mitigation for less frequent but longer disruptions

- Inventory mitigation may not be an attractive strategy when disruptions are rare but longer, since significant quantities of inventory need to be carried for extended periods

- For a given percentage uptime, mitigation rather than contingent rerouting tends to be optimal if disruptions are rare

- If volumes of the more reliable supplier are flexible, contingent rerouting (from the unreliable to the reliable supplier) can be a possible strategy

- Contingent strategies can help reduce the firm’s cost when used as a component of the optimal disruption management strategy

- For risk averse firms, mixed mitigation strategies (combining partial sourcing from more reliable sources and inventory mitigation) can be optimal

Conclusion

Tomlin ment his model not to be used for direct application in an business context, but to find out more about what factors influence optimal strategies for mitigating disruption risks. He finds that the most influential parameters are the supplier uptime and the expected disruption length, and those therefore have a great deal in defining the optimal supply chain strategy for a company.

Using these findings businesses can analyze and reevaluate their current strategies.

Tomlin, B. (2006). On the Value of Mitigation and Contingency Strategies for Managing Supply Chain Disruption Risks Management Science, 52 (5), 639-657 DOI: 10.1287/mnsc.1060.0515

Add new comment