Models for Production Planning under Uncertainty

Today will be a one-article-long-excursion in the world of production planning models.

Supply chain management of course should take a high level view of the supply and demand networks, nonetheless there is probably no supply chain which will work without physical products and most even have one or more at their core.

So production planning is a key part of a companies success.

Even in a world where companies focus on their core competencies, and may even outsource all of their production processes, knowledge about how the products are manufactured is still a vital component for understanding the supply chain and the associated risks.

Understanding the models used in production planning supports the awareness of the decision processes, which are applied in production management.

The full article can be downloaded here

Method

In their 2006 article the authors employ a literature review to gather information on which production management models are used.

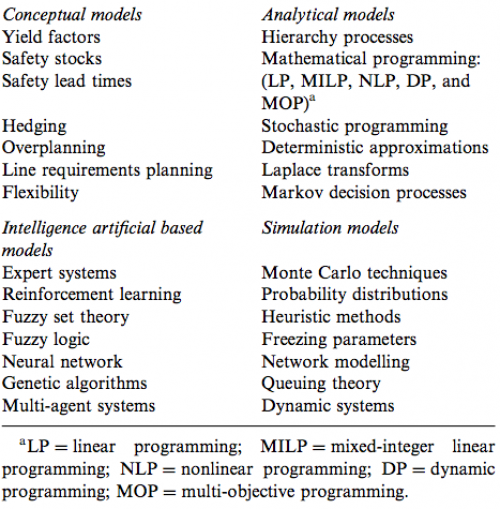

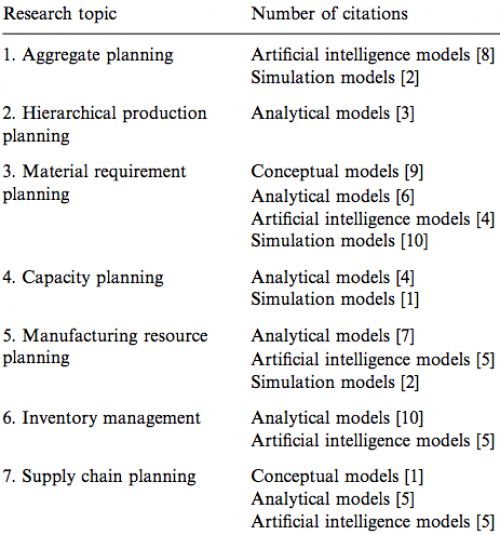

First, the authors lay the foundations for their work by proposing a classification for models of manufacturing systems (figure 1, for general models; figure 2, for models including uncertainty). For basic model types are distinguished: conceptual-, analytical-, artificial-intelligence-based- and simulation-models

Figure 1: Classification for General Uncertainty Models (Mula et al., 2006)

Figure 2: Classification Production Planning Models under Uncertainty (Mula et al., 2006)

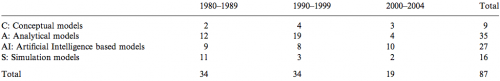

Next, in figure 3 the papers are classified according to the model type used and the decade.

Figure 3: References by Modelling Approach and Year (Mula et al., 2006)

Overall 87 papers are gathered from 1980 until 2004.

Results

Using the categorization suggested above as a frame the authors go through all the papers and add a short description for each of the 87 models. Afterwards the authors conclude:

The analytical modelling approach, in particular stochastic programming was the most frequently encountered. In the case of dynamic programming, few models were found and were mainly theoretical. Most of the analytical models addressed only one type of uncertainty, and assumed a simple structure of the production process. For more complex processes, with many different final products and more than one type of uncertainty, the analytical approach is replaced by methodologies based on artificial intelligence and simulation.

Although many works use simulation approaches to model uncertainty, very few studies exist on the comparative evaluation of the advantages and inconveniences of different simulation languages. With respect to artificial intelligence models, those based on fuzzy set theory represent an attractive tool to aid research in production management. Lastly, conceptual models with different approaches complete the taxonomy.

Conclusion

This article is a great basis to get a short (15 pages) and concise overview on production modelling under uncertainty within the last 22 years.

I was however was surprised to see that the authors did not include clues on how they selected the 87 papers. Or should we really believe that within a 22 year period there were only 87 papers published on production planning?

The authors included also a very short section on supply chain planning models, starting in 1994 with a few papers and I can therefore confirm that there are definitely gaps.

But, as said before, this really is a great overview. And if you are interested in more papers on supply chain planning just have a look here in the blog.

Mula, J., Poler, R., García-Sabater, J., & Lario, F. (2006). Models for production planning under uncertainty: A review International Journal of Production Economics, 103 (1), 271-285 DOI: 10.1016/j.ijpe.2005.09.001

Add new comment