Monte Carlo Simulation to improve Network Resilience

Today I want to describe yet another supply chain case study where Monte Carlo simulation is used as decision support for strategic / tactical supply chain decisions.

Case and approach

This time (2005) the authors, Deleris and Erhun from Stanford’s Department of Managements and Engineering, executed a case study with a company (pseudonym: Seltik): “a disguised high-tech company based in the Silicon Valley”.

As a first step the problem was formulated by the managers, who were concerned if their strategic network design was adequate for the risks their company faced.

To answer this question the authors use two building blocks: a network flow model which in turn feeds into a Monte Carlo simulation.

Risk management and network definition

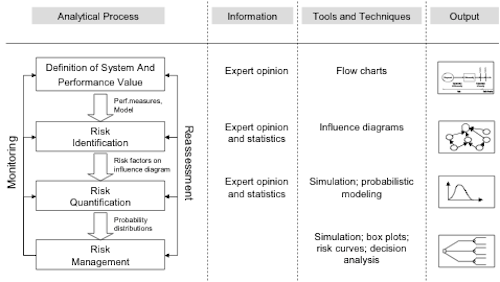

As a first step possible risks were collected and evaluated following the process depicted in figure 1. The “loss of volume” was selected as performance measure and to measure the vulnerability of the supply chain.

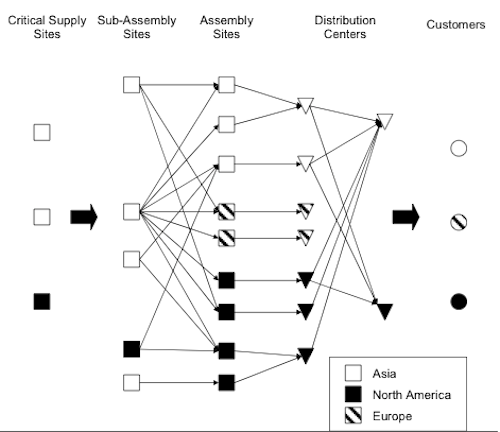

In the next step was to model and visualize the supply chain network. In this case the authors focussed only on the most profitable products. The result has been summarized in figure 2.

Flow model and simulation

The goal of the flow model is to determine the effects of a supply chain disruption to one of the nodes or links on the performance measure.

Consider for instance a single-product network composed of two paths A — d — C and B — e — C, where capital letters denote nodes and bold lower case letters denote arcs. Each path transports 50% of the product volume. Assume that A is not operating for instance due to a strike, then the loss of volume is 50%. If in addition, the arc d is broken, for instance due to a storm, then the loss of volume is unaffected.

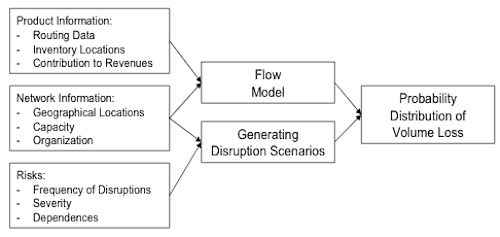

In this model a node / link can only be open or closed. The result of this analysis is a probability distribution of the volume loss. The process is depicted in figure 3.

However the flow model only results in a deterministic analysis of the network performance under risk. Monte-Carlo simulation provides the means to generate a “risk independent” statement on the resilience of the network towards a wide range of risks. The following risk events were included within the analysis:

- the possibility of employee strikes,

- the shortage of components,

- severe political instability in the various regions, and

- disruptions caused by hurricanes.

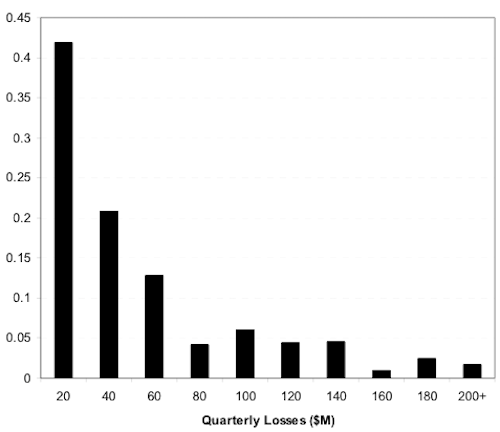

The simulation was performed using Excel and @Risk (Excel Addon) using a simplified model, with a focus on the critical (non-commodity) raw materials. The results show that in 75% of the scenarios no loss occurs, for the other 25% figure 4 depicts the contingent probabilities of the corresponding loss.

Conclusion

The model presents a possibility of how to include Monte-Carlo simulation into a decision support system. Although the paper is not detailed enough to directly reproduce the model. Nonetheless, the authors also provided the risk data which was estimated during the case.

There are a few drawbacks to using this model directly.

- The model used here is very basic and does not consider partial disruptions: links / nodes are either open or closed, nothing in between.

- Even if using Monte-Carlo Simulation to make the risks / environment dynamic, the network is still static. So there is no reaction to any disruption, like shifting sourced material to the more stable supplier.

Deleris, L.A., & Erhun, F. (2005). Risk Management in Supply Networks using Monte-Carlo Simulation Proceedings of the 2005 Winter Simulation Conference, 1643-1649

Add new comment