Supply Chain Crisis and Disaster Pyramid

With this review I take a look at supply chain disruption management. There is a huge number of actual and potential crisis (floods in Thailand, typhoons and risks of a greek collapse).

So it does make sense to think about preparation and recovery ahead of time.

Method

This article presents a new approach on how to improve preparedness and recovery after disaster strikes. It is built completely on a literature review of the resource, risk, crisis and disaster recovery, and preparedness literature. At its core this research is built on four different theories:

- resource-based view of the firm

- competing values theory, and

Disaster and Crisis Pyramid

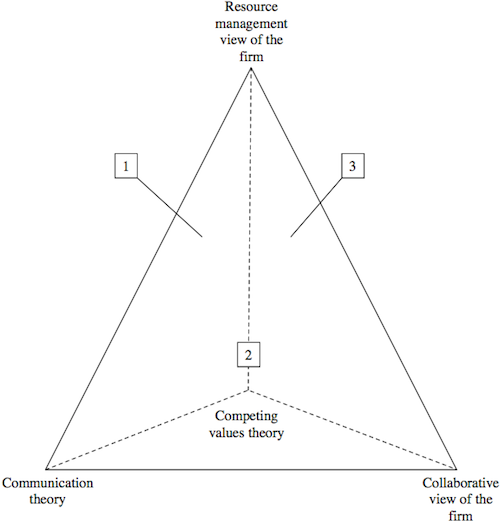

The four theories also form the pillars of the Disruption and Crisis Pyramid (DCP; figure 1).

Resource Management

The resources a company controls are an important factor in mitigating the effects of disasters. The authors summarize:

Still, given the prominence of resource management in the literature, and rightfully so, it seems logical that the DCP would “point” to resource management. Human resources must be moved from crisis locations to safe locations or from traditional operations to crisis locations. Physical and technological resources must be allocated, moved, opened, cleared, and customized. Informational resources must be collected, cleaned, warehoused, and redistributed. Financial resources must be acquired, allocated, distributed, and governed. The activity component in DCP research is huge and seems to thus be the consistent under current in the literature.

Collaboration: relationship management theory

The second element of the pyramid is the collaboration between the stakeholders in a disaster situation.

In crisis situations, collaboration will likely be the glue that holds organizations together. Additionally, Stewart et al. (2009) point out the broadness of the web that forms the extended supply chain in disaster and crisis situations. There is little doubt that such a tangled web will provide a huge opportunity for not only new research, but also to challenging the existing assumptions of relationship management logic.

Communication: communication theory

To achieve coordination and collaboration between all stakeholders, established and continued communication methods are essential.

Supply chain disaster and crisis situations demand effective communication. […] Examining issues such as bi-directionality, formality, modality, and frequency could be of serious importance as public and private entities attempt to understand what, when, and how much to communicate.

Contingency planning: competing values theory

A supply chain brings together a multitude of different companies. And usually instead of having on clear cut strategic goal, each company works for its own goals which also often are not properly aligned.

Competing values theory provides grounding for future supply chain disaster and crisis research by suggesting that firms simultaneously pursue various different and often conflicting strategic goals regardless of the situation

Conclusion

All in all Richey’s framework is aimed at providing a guideline for future researchers to find new insights into supply chain disaster management and how to improve supply chain reactions at the intersection of communication, collaboration, resources and values. And these four aspects should not only be considered by researchers, but also by supply chain professionals.

I especially liked the inclusion of the competing value theory, which might lead to a shift in research from the currently leading paradigm that goals of supply chain partners are always well aligned.

On the other hand, this framework could also be used beyond only disaster and crisis management, the aspects could perhaps prove influential in a larger number of supply chain related research fields and applications.

Richey, R.G. Jr (2009). The supply chain crisis and disaster pyramid: A theoretical framework for understanding preparedness and recovery International Journal of Physical Distribution & Logistics Management, 39 (7), 619-628 DOI: 10.1108/09600030910996288

Add new comment