Supply Risk Management from a Small Company's Perspective

This study takes a closer look at supply risk management, but this time from the perspective of several small companies. This article tries to answer the questions what risks small company owners (SCOs) see and how SCOs mitigate those risks.

Method

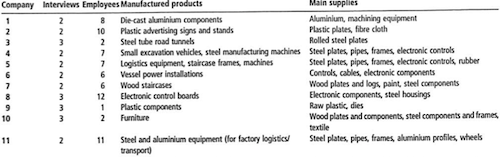

A case study with eleven small companies was conducted. The companies had between 1 and 12 employees. Overall 26 interviews were conducted (90 minutes on average). In addition, two seminars were held, to present the preliminary results and discuss the findings. The seminars were also used to generate additional data and validate existing results.

Informants rarely used terms such as supply risk, risk management, probability reduction, supply chain or even purchasing. [… So] Instead of forcing risk management terminology upon informants, possibly provoking misunderstandings and incomplete accounts, the idea was to let the SCOs provide rich accounts of their purchasing and SCM practices in layman’s terms. In the dialogue information was sought out that allowed plausible interpretations of supply risk management practices.

Figure 1 summarizes some facts about the companies.

Risk mitigation approaches

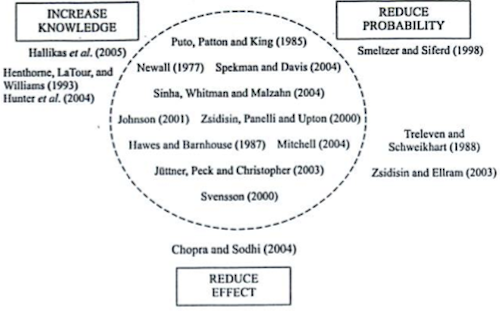

From literature the author develops three types of supply risk management / mitigation activities, namely: increased knowledge, reduced probability and reduced impact (figure 2).

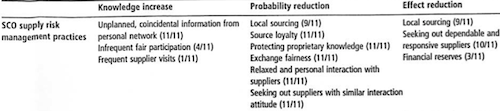

Knowledge

Knowledge increasing practices were infrequent among the studied SCOs. They spend limited time and resources actively acquiring knowledge about suppliers and supply markets and therefore possessed limited information […]. Only one SCO interacted with suppliers often.

Probability reduction

Probability reduction had the highest priority in these companies. Elimination of severe risks formed the backbone of SCO practices. […] In order to eliminate certain severe risks, the SCOs sourced locally, exhibited source loyalty, and were careful not to reveal proprietary product knowledge to suppliers.

Effect reduction

None of the SCOs held reserve capacity and practiced mainly single sourcing, with the aim of tying up as few resources as possible. The very limited reserves left the SCOs quite vulnerable to certain types of risks. Any specific events with the potential to obstruct delivery capabilities of suppliers, such as a fire, take-over, bankruptcy, up-stream material shortages etc. could bring SCO production to a halt.

All results are summarized in figure 3.

Lessons learned

Despite the autodidact and informal purchasing practices of

the studied SCOs, there may be much to learn from these practices, even for state-of-the-art purchasing/SCM departments. The SCOs specialised in a few supply risk management practices that seemed to complement each other well. The study suggests that effective supply risk management is not only about adopting a wide range of sophisticated risk reduction practices. The challenge may be more connected to finding the right mix of practices, which fits the available resources and is sufficient to secure against supply risks. Supply chain managers should realise that:

- different supply risk management practices require different levels of expertise and resources;

- only a limited number of potential supply risk management practices may be necessary; and

- supply risk management means adopting the exact mix of practices that provides security.

Conclusion

This study provides some missing insights into risk management practices of small enterprises. As the author, I do think that there are still things even larger companies can learn from their mitigation strategies: Prioritization and focus of risk management activities which deem to be most effective with the given resources may be one of those.

Ellegaard, C. (2008). Supply risk management in a small company perspective Supply Chain Management: An International Journal, 13 (6), 425-434 DOI: 10.1108/13598540810905688

Add new comment