Simplified Supply Chain Flows

I have to distract myself a little bit from thinking about supply chain risks too much, so I thought why not use the chance to read a different article once in a while. Well, at least the authors are familiar: Paul Childerhouse and Denis R. Towill and their paper of 2003: “Simplified material flow holds the key to supply chain integration”

Pre-work

Childerhouse and Towill start with an historical analysis of applications of simplified material flows, starting in the 16th century with the progress made in the supply chain for war ships over to the description of the bullwhip effect all the historic examples are concerned with the simplification of the supply chain, where the…

…emphasis is on “clean” i.e. unbiased and noise-free information flows; time compression of all work processes; achievement of consistent lead times; choice of smallest possible planning period; adherence to the schedule i.e. elimination of pockets of “Just-in-Case” materials, selection by simulation of the “best” supply chain controls; and finally, matching the simulation model to the real work process via process flow and information analyses

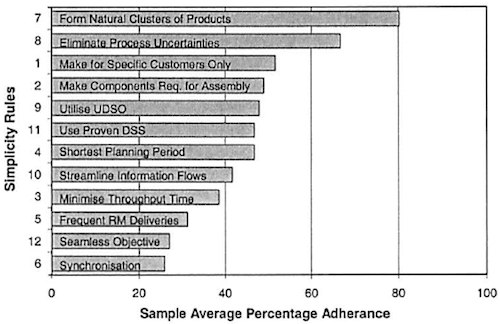

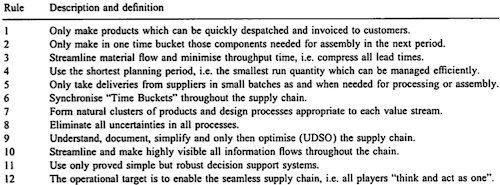

In previous papers the authors already analyzed how supply chain simplification is possible and conclude with a list of simplification rules (Figure 1).

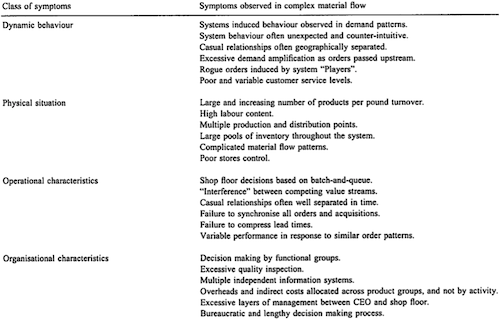

Figure 2 shows symptoms of a supply chain, when the material flows are too complex.

Method

A case study with 23 value streams all across Europe have been analyzed and a degree of simplification has been calculated using a score for the above mentioned simplification rules.

Results

The authors present five hypothesis to test using this data:

- The effectiveness of a supply chain can be measured by assessing the level of uncertainty for the four segments of supply, process, demand and control.

- Conformance to the 12 simplicity rules reduces uncertainty and results in increased supply chain integration.

- On average each of the 12 simplicity rules are adhered to equally.

- The level of uncertainty in the supply chain can be determined from a set of dynamic behaviour, organisational, situational and process observations.

- Companies that undertake major Business Process Re-engineering programmes via the application of the 12 simplicity rules reduce uncertainties in their supply chains.

The hypothesis one and two are supported by the data of the sample. Hypothesis three is rejected, since the authors find that in the sample some of the simplicity rules are implemented more often then others (figure 3).

The fourth and fifth hypothesis are validated as well.

The authors conclude:

Practitioners are faced with a multitude of published alternative ideas and techniques to improve the performance of their supply chains. It can be seen that most of these proposals have their roots in simplified material flow.

Conclusion

So, what do I want to remember from this detour:

- Uncertainty is a driving force behind supply chain inefficiencies and risk reduction therefore also a way to improve performance.

- Supply chain simplification is according to the authors one of the most common, yet often renamed, ways to reduce uncertainty and improve performance

And I thought I would get rid of risks for now…

Childerhouse, P. (2003). Simplified material flow holds the key to supply chain integration Omega, 31 (1), 17-27 DOI: 10.1016/S0305-0483(02)00062-2

Comments

I like your research very much and would like to get copy of the whole research. I am an Egyptian Pharmacist, enrolling now for Ph D degree at Maastricht School of Business. I am now preparing my proposal. It will be for assessing the supply chain among pharmaceutical arena in Egypt and Saudi, where I am working now. I choose the qualitative method and I read that your paper is considered one of the few best that used qualitative approach in a perfect way. I will appreciate your help very much since I am struggling to find references in this field using qualitative method. Thanking you in advance and best regards.

Mohammed Ali

Operations Manager - IMS Health - Saudi Arabia operation.

Add new comment