Agile Supply Chains

I have been reading a lot of interesting articles lately, hence I could not post as often as I wanted. I found an article by van der Vorst and Beulens (2002; “Identifying sources of uncertainty to generate supply chain redesign strategies”) which opens a new perspective on the SCRM issue. I am going to publish a review later this week and link it here.

Today I wanted to highlight the basics of supply chain management by talking about “Supply chain migration from lean and functional to agile and customised” by Christopher and Towill (2000).

Agile supply chains are a quite new concept which emphasis a change in the corporate mindset to adjust to the constantly changing customer demand.

Agility

Agility is described as a capability which contains organisational structure, information systems, logistic processes and mindsets.

Result of an agile supply chain is its flexibility. It has to be separated from the lean supply chains or the lean manufacturing concept which focusses on reducing “fat” (eg. inventory, cost, …) wherever possible.

Market qualifiers / Market winners

Why does this change happen? According to Christopher and Towill there is a constant change of the factors which contribute to the market qualifiers and the market winners (based on Hill (1993)).

Hence periodically a new market winner emerges and downgrades the previous market winner to a market qualifier

For example in the early 80s the market winner was quality, in the late 80s it was cost. Presently the authors identified lead time as the new market winner.

Agile Logistics

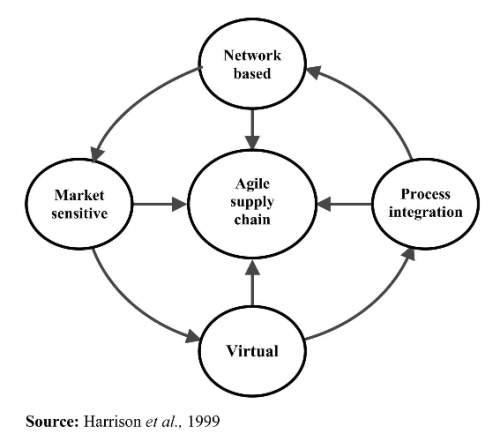

Agile Logistics are defined by the four basic elements shown in the graphics.

So one part of designing an agile supply chain is the decision about where to place the decoupling points. There can be two different decoupling points one for the information decoupling (up to where in the supply chain is the information about customer demand shared) and the placement of strategic inventory.

Conclusion

This is a very good article to explain the basics of agile supply chains. There are many followers building on this work. But up to now I have not been able to find one article dealing with the measurement of agility or flexibility. This should be very useful for analyzing adequate measures to achieve agility.

Christopher, M., & Towill, D. (2000). Supply chain migration from lean and functional to agile and customised Supply Chain Management: An International Journal, 5 (4), 206-213 DOI: 10.1108/13598540010347334

Comments

A VERY GOOD ARTICLE

Add new comment