An Empirical Investigation into Supply Chain Vulnerability

One basic assumption in risk-aware supply chain design is the notion that the design of the supply chain actually has an impact on the vulnerability of the supply chain.

This question has been analyzed about six years ago in a broad empirical study by Wagner and Bode.

Method

The authors use a rather large sample of companies in Germany. Overall nearly 5000 supply chain professionals were asked to participate and 760 actually took part in the study.

Most sample companies had an industrial focus (72% versus service (20%) and trade (9%)).

This study is founded on a similar sample as this other study by Wagner and Bode analyzing the impact of risks on supply chain performance.

Model

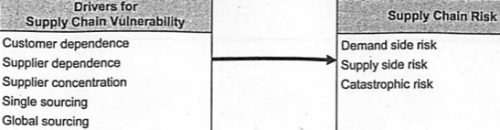

The author focus on some supply chain design variables, which supposedly increase supply chain vulnerabilities. Figure 1 shows the assumed relationship between those drivers of supply chain vulnerability and three supply chain risk categories.

Figure 1: Concept: Relationship between Design and Risk

The authors propose the following hypothesis, which are then tested using the empirical data:

- H1: The higher the drivers of supply chain vulnerability, the higher the level of demand side risk a firm faces.

- H2: The higher the drivers of supply chain vulnerability, the higher the level of supply side risk a firm faces.

- H3: The higher the drivers of supply chain vulnerability, the higher the level of catastrophic side risk a firm faces.

Results

The results show that all hypothesis are supported by the findings of the authors. However the design factors/vulnerabilities only explain part of the observed supply chain risks (7% for H1, 13% for H2, 3% for H3).

Demand side risk was influenced by strong customer dependence and strong supplier dependence.

Supply side risk was influenced by supplier dependence, single sourcing and global sourcing.

Lastly, catastrophic risk was impacted by the degree of global sourcing.

The authors draw the following conclusions:

First, the supply chain vulnerability variables in our model explain a rather small portion of the variance in the risk arising from demand side risk sources. It is a low but not astonishing value since the majority of the vulnerability variables focuses on the upstream supply chain. However, the results reveal that customer dependence increases demand side risk. This finding indicates that firms that are dependent on some customers are exposed to a higher risk of suffering from the detrimental effects of demand volatility and poor downstream information. This could be because of order batching or limited possibilities of demand pooling. […] This leads to the hypothesis that, beyond the investigated variables, there are several additional aspects both internal and external to the supply chain that determine a firm’s exposure to supply chain risk.

Second, risk derived from supply side risk sources is elevated by supplier dependence, single sourcing and global sourcing. Supplier dependence obviously amplifies the threat from poor quality, supply shortages, sudden demise of one of these suppliers, and poor logistics performance. Although this argumentation also applies to single sourcing, the single sourcing approach seems to be less hazardous than general dependence on some suppliers. This is because single sourcing is usually aligned with a closer relationship that might absorb some of the supply side risk.

Third, when it comes to risk from catastrophic risk sources it has to be taken into consideration that the sample data was collected in Germany which has been a very “calm” place with regard to disasters. Here, it is solely global sourcing that is a significant factor that exposes firms to higher risk from catastrophes. The implementation of a global sourcing strategy stretches the supply chain geographically which ultimately means more peril points for the information and material flow. The robustness and resilience of regional or national supply chains is usually higher. Surprisingly, the study shows that supplier dependence decreases the risk exposure to catastrophes. Again we would argue that this is because of lack in supply flexibility. Firefighting against the consequences of catastrophic events might be more successful with the ability to quickly adjust the supply.

Conclusion

I would argue that it is always hard to measure risk consistently in a qualitative study. People are likely to evaluate the same risk quite differently, which might lead to unclear results.

Furthermore the low impact of these specific design variables emphasizes the view that there are many more factors (internal and external) that impact the exposure to supply chain risk.

Wagner, S.M., & Bode, C. (2006). An Empirical Investigation into Supply Chain Vulnerability Experienced by German Firms Erich Schmidt Verlag, 79-96

Add new comment