Behavioral Risks in Supply Networks

Not only earthquakes and terrorist attacks can lead to supply chain disruptions. Supply chains are also subject to behavioral risks, meaning that participants of the supply chain could exhibit behavior which might be consistent with their goals, but contrary to the goals of the supply chain’s other participants.

And so one has to ask: How should a company mitigate behavioral risks? And this is what Seiter did and his work was published as chapter 15 of another great book on supply chain risks (Supply Chain Risk by Zsidisin and Ritchie), which can be bought at amazon.com, if you are interested in reading more.

Methods

Seiter starts with the assumptions of the principal agent theory where interactions between individuals, which are built on asymmetric information may lead to problems for either or both parties.

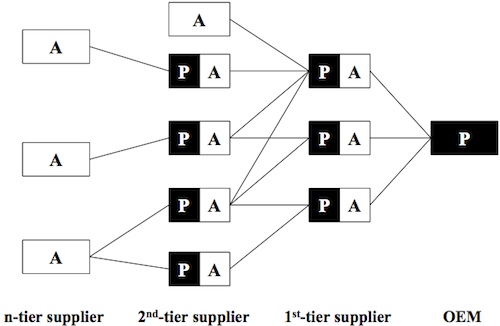

Figure 1 shows the principal-agent relationships in a supply chain.

Next, a preliminary study was conducted to gather information on the strategies which are employed in practice. Ten companies were interviewed and the following strategies were found to be the most frequently used:

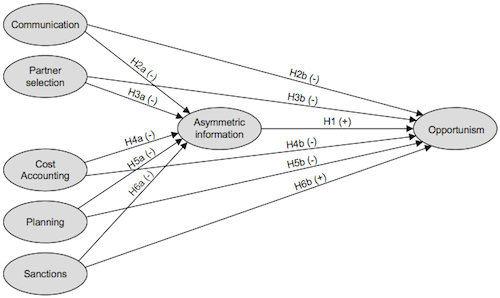

- Communication: Communication is the formal and informal exchange of information between the partners within the supply network. There are many different forms of communication, e.g., oral communication or written communication. All forms of communication have in common that they reduce the degree of asymmetric information. But, the size of this effect depends on the frequency and quality of the communication.

- Partner selection: Partner selection is the examination of the match between the potential partners in a supply network (Das and Teng 2003). From a sequence perspective the selection of appropriate partners is the first instrument to prevent the opportunistic behaviour of suppliers. The literature suggests many recommendations concerning the selection criteria to use (for an overview see Seiter and Isensee 2007). By using a set of criteria the partner selection process seeks to ensure partner “fit”. There are different types of fit, e.g., strategic fit, and resources fit (Das and Teng 1999). However, the most important fit is the fit of the partners’ objectives. Only if all partners in the supply network can reach their goals simultaneously, will dysfunctional behaviour become unlikely (Das and Teng 1999).

- Inter-organizational cost accounting: A typical form of opportunistic behaviour a supplier can practice is the abuse of the information asymmetry. For example, to pretend that costs are higher and accordingly seek a higher price. In practice different forms of inter-organizational cost accounting may be implemented to avoid such behaviour. The forms vary from partial approaches to full approaches like open-book accounting (Kajüter and Kulmala 2005).

- Inter-organizational planning: Another way to prevent opportunistic behaviour is to reduce the extent of asymmetric information by sharing planning data. Several concepts have emerged in practice like “collaborative planning, forecasting and replenishment” or “supply chain planning”. The diffusion of inter-organizational planning is also supported by a great variety of software solutions that support the structured planning along the supply network.

- Sanctions: Sanctions, in the event of the occurrence of opportunistic behaviour, are one of the first instruments mentioned by each interviewee. Normally, sanctions are defined in the formal bilateral contracts between buyer and supplier (Wuyts and Geyskens 2005). Especially, in cases where product-specific information is shared in the partnership between buyer and supplier, the contracts include paragraphs preventing the abuse of this information. This is more often the case when it comes to international supply networks.

As a second step the influence of these strategies is tested using a qualitative survey.

Figure 2 shows the proposed hypothesis. It considers not only direct effects on the opportunistic behavior but also indirect effects, which support the build-up of asymmetric information.

Results

The author finds some clear results regarding communication and inter-organizational cost accounting, which both significantly help to reduce opportunistic behavior within the supply chain. But, “no significant effects regarding possible sanctions and inter-organizational planning systems were found.” Furthermore, there was a positive correlation between partner selection efforts and opportunism was found indicating that higher efforts could lead to higher opportunism.

To explain the non-significant results, the author conducted a focus group discussion which lead to the following plausible explanations for the findings:

- The group came to the conclusion that sanctions cannot provide perfect protection as all future circumstances would have to be anticipated and planned for accordingly.

- The absence of the anticipated effect of inter-organizational planning could be grounded in the construct itself. In practice several different types of planning systems do exist, some very simple and others very complex types. The effective operationalization of this construct may require the indicators to be more specific about the specific types of planning systems used.

- [Regarding the positive correlation between partnerselection and opportunism:] The survey captures only the initial partner selection effort but not whether partners are tested continuously. Therefore, this unexpected result may possibly be due to the need to define the indicators more closely to include this possibility.

Finally the author concludes, that “communication seems to be the central factor for preventing opportunistic behaviour in supply networks. For this reason the improvement of communication should be a primary objective.”

Conclusion

I liked the study design due to its concise structure and the extensive elaboration on the study methods. The results show, that there still is room for improvement. A more detailed model might have lead to more significant results with the other strategies employed.

Seiter, M. (2009). Behavioural Risks in Supply Networks Supply Chain Risk - A Handbook of Assessment, Management, and Performance, 235-247 DOI: 10.1007/978-0-387-79934-6_15

Add new comment