Case Study on Managing Disruptions in Supply Chains

Disruptions are an often recurring research objective in this blog. After writing about the severity of disruptions and conceptual research on how to mitigate them, todays article is concerned with how disruptions are managed in practice.

Research Questions & Methodolgy

From their literature review the authors deduct the following research questions:

- What are the different types of risks in a retail supply chain?

- What are the mitigation strategies required to manage different types of supply chain risks?

To answer those questions a case study is conducted with a retail supply chain in focus. The supply chain consists of a large retailer for pet products and several manufacturers and vendors in North America. The product flow is usually from the producer to the producer’s distribution network, the retailer’s distribution network and finally to the stores. For the case study several interviews were held with employees from the retailer and two of the vendors.

Risk Categorization and Mitigation

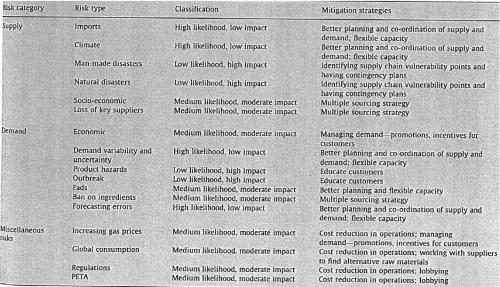

The interviews led to a categorization of supply chain risks (supply, demand and miscellaneous risks), with corresponding sub-categories, like natural disasters in supply risks or economic risks on the demand side.

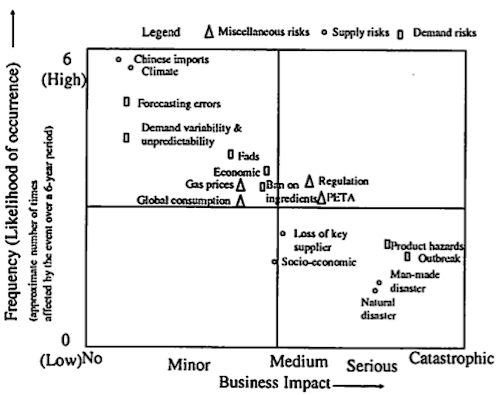

The risks are then aggregated in a matrix with the business impact on the x-axis and the frequency / likelihood on the y-axis (see figure 1).

The authors conclude:

Most supply chain risks fall into two fairly distinct categories—high-likelihood, low-impact risks (or inherent and frequent risks) and low-likelihood, high-impact risks (or disruption and infrequent risks). However, a few will have moderate likelihood of occurring and moderate impact We argue that the classification of a specific type or category of risk may depend on the type of supply chain in question or on contextual characterization or in fact on the supply chain design.

Two types of strategies can be used: generic strategies, which are applicable for a broad range of risk types, and specific strategies, which can only be used for specific risks. From the case study the authors further conclude that specific strategies are primarily used with risks that tend to increase the cost of doing business in a retail supply chain (e.g. increasing gas prices). Generic strategies on the other hand with a focus on coordination of supply and demand can be used to mitigate high-likelihood, low-impact risks. Disruptions require specific strategies which identify the weak point in a supply chain and mitigate by contingency planning.

The aggregated results can be found in figure 2.

Conclusion

To reap general recommendations from this research one had to perform a representative survey. But the results of Oke and Gopalakrishnan can be used as food for thought by practitioners. Are your risks more more frequent or less frequent? How about their respective business impact? Are you using different strategy types for different risks?

If you are interested in more articles on supply chain disruptions and their effects have a look at the Disruption category here in the blog.

Oke, A., & Gopalakrishnan, M. (2009). Managing disruptions in supply chains: A case study of a retail supply chain International Journal of Production Economics, 118 (1), 168-174 DOI: 10.1016/j.ijpe.2008.08.045

Add new comment