Leading by Design

Is there consensus about the role of product design as the leading function in the supply chain? Not yet! This article introduces the topic of integrating decisions in product and supply chain design and gives a short glimpse on the “how to implement” part.

Case study

During the last weeks I conducted the following case study on the impact of product design on supply chains using literature and expert interviews, looking for an answer to the basic question: What are the advantages of integrating product design into your supply chain decisions?

- European retailer for furniture

Supply chain management starts with the product design. They are using this integration to reduce cost but also carbon emissions. One example, the packaging they use is designed for the specific transportation requirements so that efficiency is raised.

- Marks & Spencer, UK Are using their product design as an integrated part of its overall risk management. Apparel design is also leading procurement decisions (see reference for more information).

- Big European food company

Product design is lead my marketing function. Supply chain design is guided by those decisions.

Research

In the literature Khan et al. 2008 also take the view that product design and supply chain design should be integrated more to improve overall results. They first state that product design is usually neglected in corporate risk management. To minimize risks the authors recommend to establish “design led procurement” and “design-led risk management” to improve agility, relationships with suppliers, while on the other hand avoiding over dependence.

How To

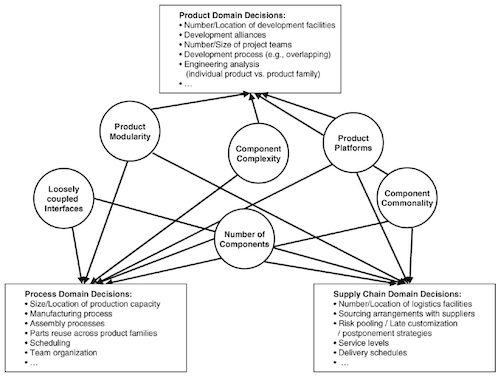

Fixson (2005) introduces a framework for an integrated decision making of product, process and supply chain decisions. Decisions taken within those three domains depend on six different product characteristics:

- Product modularity

- Component complexity

- Loosely coupled interfaces

- Number of components

- Product platforms

- Component commonality

a guideline to focus on design decisions critical for the product and company under consideration; [… it can help to] explore the advantages and limitations of various operational strategies for given product architectures [… and] to improve a company’s strategy planning capabilities over time.

Conclusion

From systems theory it should be obvious that integrating decision making should lead to better results than decisions in separate functions. But the mentioned examples are only a skewed sample to emphasize the point: Yes, it makes sense to integrate product development. But the implementation has to be thoroughly planned.

Khan, O., Christopher, M., & Burnes, B. (2008). The impact of product design on supply chain risk: a case study International Journal of Physical Distribution & Logistics Management, 38 (5), 412-432 DOI: 10.1108/09600030810882834

Fixson, S. (2005). Product architecture assessment: a tool to link product, process, and supply chain design decisions Journal of Operations Management, 23 (3-4), 345-369 DOI: 10.1016/j.jom.2004.08.006

Add new comment