Managing Global Sourcing Risk

Probably most companies source at least some parts for their products from global sources. This could be the steel from Australia, electronics from Taiwan or cloth from India. The reasons for international sourcing usually include cost and quality, which might be superior compared to local sources.

On the other hand longer shipment ways and less direct access and control may also increase the risks of quality failures, delays or even disruptions.

So at the moment a lot of companies struggle to find the right balance between increased risks and reduced cost in international sourcing. This study gives an inside view into fifteen companies and how they handle risks related to global sourcing, and therefore this overview is a good example for current practices in the field of supply chain risk mitigation.

Method

The authors still see a gap in the knowledge about how other companies analyze their sourcing related risks and how these risks are mitigated by them.

Therefore they use a multiple case study approach with 15 cases / companies within seven industries. In each company several information sources were tapped, including expert interviews.

Afterwards the authors compared the individual results in a cross case analysis.

Sourcing globally

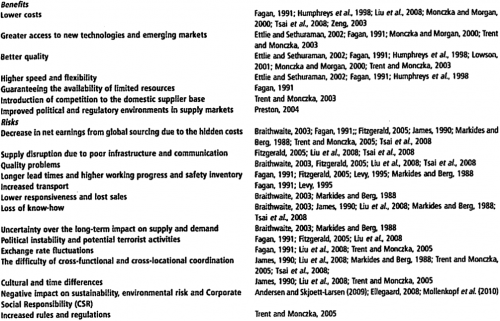

But first the authors start with a literature analysis to analyze the reasons and risks of global sourcing.

Figure 1 shows their results regarding the advantages and risks of sourcing globally.

Figure 1: Sourcing Globally: Advantages and Risks (Christopher et al., 2011; click to zoom)

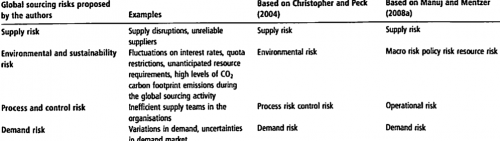

From this the authors extract a risk classification for global sourcing risks (figure 2).

Figure 2: Sourcing Globally: Risk Classification (Christopher et al., 2011; click to zoom)

Risks in global sourcing

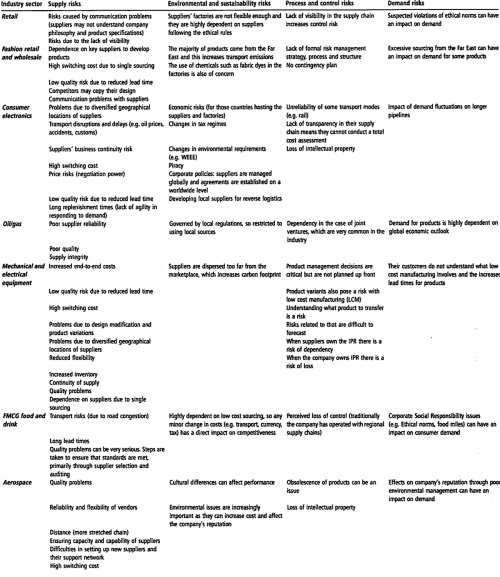

Building on this literature review the authors conduct their case study. The cross-case analysis reveals risks in the following industries:

- retail,

- fashion retail and wholesale,

- consumer electronics,

- oil/gas,

- mechanical and electrical equipment,

- fast moving consumer goods (food and drink), and

- aerospace.

The risks are shown in figure 3.

Figure 3: Risk Overview (Sourcing Globally) (Christopher et al., 2011; click to zoom)

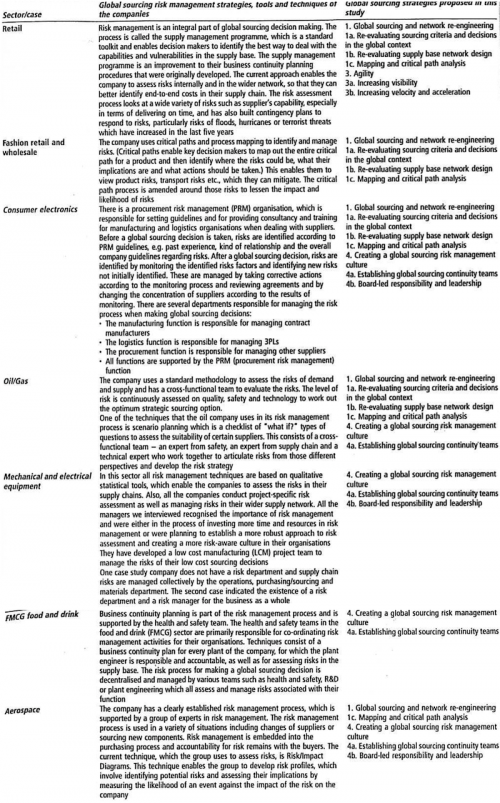

Strategies for risk mitigation

The identified risks are handled very differently by each of the companies. Figure 4 shows the different approaches to identify and manage the risks.

Figure 4: Risk Management Strategies and Tools (Christopher et al., 2011; click to zoom)

Overall the authors find:

The study proposes four generic strategies for managing global sourcing risk: network re-engineering, collaboration, agility and a risk management culture. Evidence of each of these strategics was found in the case studies although no single company was applying all of them.

The study also shows that even though many managers were aware of the risks their companies were exposed to, risk management strategies were not implemented in a systematic and holistic manner.

Conclusion

It is not possible to generalize these results for any company, due to the specific exploratory nature of the method used. But I find the findings quite interesting and I think they could be used as a foundation to build your own mix of mitigation strategies.

Christopher, M., Mena, C., Khan, O., & Yurt, O. (2011). Approaches to managing global sourcing risk Supply Chain Management: An International Journal, 16 (2), 67-81 DOI: 10.1108/13598541111115338

Add new comment