Managing Supply Chain Portfolios

A supply chain usually does not stand alone. Frequently a supply chain is defined by the need of the end customer which has to be satisfied. Since one company commonly deliver several products, within a single company there can be multiple different supply chains aggregated under one organization. This task of managing multiple supply chains is most often referred to as Supply Chain Portfolio Management. It is still in a very early stage of research, so there are only few researchers focusing on this part. But today’s article employs this portfolio point of view and is concerned with the question of how adaptive a single supply chain has to be.

Setting and method

The authors pose the following questions:

- Under which conditions does the firm need a strategy of high adaptation and when might medium or low adaptation be sufficient?

- To what extent may product portfolio decisions moderate the level of supply chain adaptation required?

- To what extent does the level of supply chain adaptation impact the optimal configuration of a firm’s supply chain portfolio, e.g. the number of production facilities?

The authors develop several mathematical models to address these question, overall four models (building on one base model) are used to represent different states of adaptability:

- A no adaptation model, in which every product that is delivered in different planning periods has to be brought out via the same supply chain.

- A low adaptation model, in which products may be reassigned to different transportation modes, for example from air cargo to ocean freight.

- A medium adaptation model, in which products may additionally be reassigned across the firm’s production facilities.

- A high adaptation model, in which the firm’s entire manufacturing footprint, product- to-facility assignment and transportation modes may be updated over time.

So the ability to adapt a specific supply chain is differentiated into no, low, medium and high adaptability. Whereas the business dynamics are divided into global business trends and product portfolios dynamics.

Results

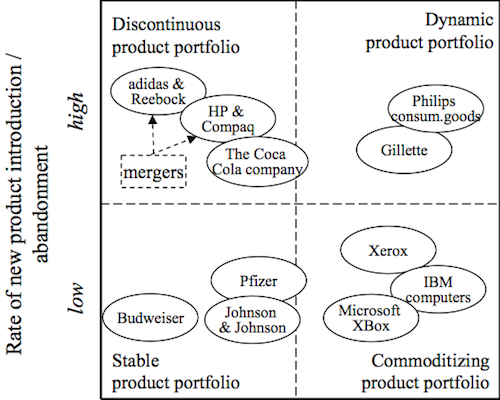

Based on numerical experiments with their models the authors develop the following framework to differentiate product strategies and supply chain adaptation (figure 1).

Four types of product portfolios are revealed, based on the rate of product commoditization (x-axis) on the rate of the new product introduction (y-axis).

- Stable product portfolios, show only low adaptation rates and do not need them due to specific environmental factors. Nonetheless adaptation might be required due to global business dynamics.

- Commoditizing product portfolio: “We refer to a product portfolio as commoditizing if the products characteristics change at a high rate, while relatively few products are introduced or abandoned from the product portfolio.”

- Discontinuous product portfolio: “If a product portfolio doesn’t exhibit significant commoditization, but an important number of products are nevertheless added or abandoned, we refer to it as discontinuous.”

- Dynamic product portfolio: “We refer to a product portfolio as dynamic if the products in the portfolio commoditize at a high rate and, at the same time, the rate of product introduction and abandonment is high.”

Overall the authors conclude:

Insight 1: Our results indicate that although supply chain adaptation may indeed be important for a firm to retain its competitiveness, the need for it differs widely across firms. Important drivers to determine the value of supply chain adaptation in response to product portfolio dynamics are the commoditization rate a product portfolio experiences and the distribution of product types in the portfolio over time. While the commoditization rate of a product portfolio is highly industry-dependent and thus mostly exogenous to the decision-maker, the firm can actively manipulate the distribution of product types over time, e.g. ensuring a stable distribution of product types over time.

Insight 2: By balancing product decisions and supply chain adaptation strategy, a firm may weight how much supply chain adaptation it is ready to pursue to support its competitive strategy

Insight 3: This flexibility to respond to business dynamics by either supply chain adaptation or product portfolio renovation may be reduced if high global business dynamics necessitate high adaptation per se.

Insight 4: Finally, to exploit the full potential of supply chain adaptation a firm should carefully design its supply chain portfolio according to the adaptation strategy employed. Optimal supply chain portfolios may vary significantly in the number of production facilities and supply chains in use.

Conclusion

Using their classification schemes the authors were able to analyze their models in depth and unveil several key findings to guide a strategic supply chain portfolio management based on company internal and external factors.

Business dynamics pose risks and imply the need to adapt to this changing environment, but not all companies need to have the same level of adaptability for their supply chains.

Seifert, R.W., & Langenberg, K.U. (2011). Managing Business Dynamics with Adaptive Supply Chain Portfolios European Journal of Operational Research

Comments

Thanks for the insight. I haven't seen this segmentation before.

I wrote some examples of product segmentation in the supply chain

If you're interested: http://supplychaintrends.wordpress.com/2011/04/16/supply-chain-focus-foc...

cheers,

Niels

Add new comment