Matching Product Architecture with Supply Chain Design

This review is about a preprint article which already has been accepted for publication by the “European Journal of Operational Research”. But since there is only a limited space for articles in each issue of the journal, final publication of the article is delayed.

One could now argue in a general note that this behavior also signifies a delay of the progress of supply chain research over all, with all its negative long term effects. Furthermore, in the days of the internet journals should not limit themselves to an artificial (article) limit, but see only the sky or in this case the number of quality publications as their limit.

But in this case I was able to gain access to an early copy.

Product design & supply chain management

I already wrote several times (1, 2, 3, 4) on how product architecture and supply chain design could be integrated, so this is not really a new topic. But it also touches a more integrative approach of supply chain management.

Building from the early models, where a supply chain could easily be defined by a handful of properties, supply chain models nowadays reach a new level of complexity. One of these extensions is the integration of supply chain activities into the product development process, which is supposed to yield (if we trust case studies like IKEA) enormous benefits in every performance aspect of the supply chain and ultimately the company.In the study reviewed Nepal, Monplaisir and Famuyiwa first develop a conceptual and mathematical model to integrate the supply chain design decisions into the product development process. In a second step this model is then tested using two case studies.

Model

The authors suggest an integrated three step process: 1) selection of product architecture, 2) evaluation of potential suppliers, and 3) optimal configuration of supply chain.

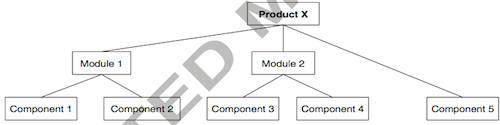

The first step includes the development of a generic bill of materials (GBOM) for every possible product architecture scenario. Figure 1 shows the GBOM for an example Product X.

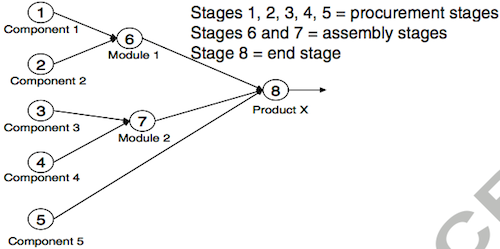

This product design also leads to a similar generic supply chain structure which is shown in figure 2.

The second step focusses on the identification and evaluation of available the supply chain participants. Necessary information, like production cost, lead-time and compatibility index has to be collected.

The compatibility index itself is developed by the authors as well and contains information on the compatibility of this potential supplier regarding the structural, managerial and financial dimension. Each of the dimensions is then weighted to generate the complete index. Since the compatibility of the future suppliers is hard to judge before the product is even designed, the authors employ fuzzy logic, allowing them to use ranges for each of the compatibility indices instead of fixed numbers.

The last step aims to find the optimal supply chain configuration. This is done for each product architecture scenario by using a linear goal programming model, where total supply chain cost are minimized while maximizing the compatibility between the partners.

Case studies

There are two case studies, one on bulldozer assembly and manufacturing and the other on an automotive climate control system. I will only talk about the first case since I found it more interesting.

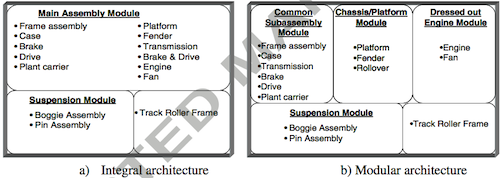

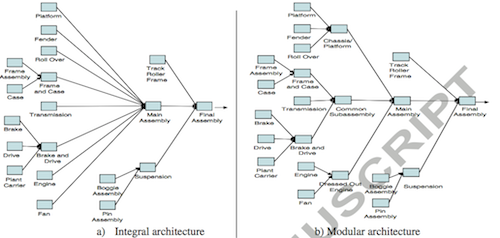

For the case the authors exercise the three steps mentioned above. First they design two different product architectures (integral and modular architectures; figure 3) and the corresponding generic supply chain networks (figure 4).

Lastly, the authors collect the necessary information of the potential suppliers regarding cost, lead-time and ranges for the compatibility index for two different process options:

Two alternatives are considered for each node. If the node is a procurement stage, the first alternative represents the standard supply option (that is, the existing procurement arrangement). The second option represents a consignment option where the supplier is responsible for providing immediate delivery to the bulldozer line. Similarly, for the assembly node, the first option represents the standard manufacturing method while the second option represents an expedited alternative that corresponds to a supplier who has invested in process improvement efforts in order to decrease its supply lead-time.

After solving the model in the next step, the authors conclude:

In the majority of the bulldozer supply chain stages for a modular architectural design, option two has been selected. While it is more expensive than option one, option two has a lower production lead-time and higher compatibility ratings for all stages because its modularity increases the degree of dependency, based on relative costs of inputs, between supply chain nodes.

Compared with base results, where only supply chain costs are considered, this model delivers a solution which performs (slightly) worse in cost (+0,36%), but on the other hand has the potential to deliver a much more balanced and robust solution considering also compatibility issues.

Conclusion

I found the paper to be a great read and I cannot add anything else to the issues the authors already detected and mentioned in their own conclusion:

- Risk factors are missing in the model (e.g. random service times)

- Additional factors like sustainability and flexibility should be considered

- It is very obvious that this is again a supply oriented model, so it would be great to see how distribution network decisions behave when including product design decisions (since the customers might also change depending on the product design decisions)

Nepal, B., Monplaisir, L., & Famuyiwa, O. (2011). Matching Product Architecture with Supply Chain Design European Journal of Operational Research : 10.1016/j.ejor.2011.07.041

Add new comment