Risk-based Classification of Supplier Relationships

A large proportion of the efforts in supply chain risk management focus on the supply side, even though, using common definitions of supply chain management, the supply chain of course not only contains the suppliers but also the customers down to the end-customer.

Focussing on the supply side, Hallikas et al. 2005 studied the different classes of supplier relationships and what risk mitigation strategies might be effective with these classes. This classification can help both affected parties, in understanding the effects of risk on their relationship.

Methodology

The authors conducted a single-case study with a high-tech OEM from Finland. To analyze the company’s relationships with its first tier suppliers, 42 of them participated in a survey on relationship parameters and the risks involved.

The goal was to support or reject hypothesis regarding the collaborative learning (“H1: Collaborative learning in supplier relationships differs according to the type and extent of the risks involved.”) and risk management (“H2: Risk-management practices vary according to the type and extent of the risks involved in supplier relationships.”).

Risks and collaboration

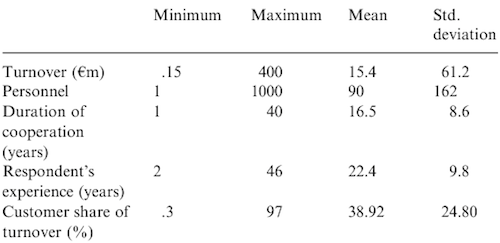

The suppliers in the sample are described in figure 1. Most of the respondents were in CEO or Director positions.

Four different generic, relationship risks were considered:

- Hold-up risk

describes how specific the assets for this relationship are and if they could be used again outside of the relationship. Example: A computer would pose little hold-up risk, whereas a specific machine which only produces a product for a specific client would pose a high relationship risk. - Demand risk

is high, when demand fluctuations are rapid and significant. - Replaceability risk

is the chance of the OEM to being able to replace the supplier. - Value added

the importance of the supplier towards the end product.

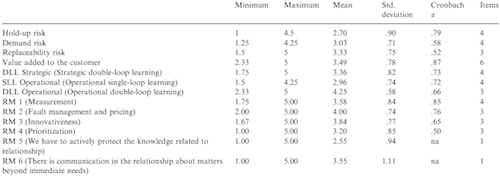

Those risks were evaluated by the survey participants, if they are important for the specific relationship (see figure 2).

Further on the participants were asked about their collaboration efforts in the following categories:

- Operational single-loop learning (SLL Operational)

refers to collaboration with the goal of small, incremental improvements. - Strategic double-loop learning (DLL Strategic)

aims at long term efforts with mutual investments to improve the capabilities. - Operational double-loop learning (DLL Operational)

refers to drastic operational improvements, which require close collaboration.

Six risk management measures have been part of the survey as well. Starting with measures which do not require intensive collaboration like “Measurement” of the relationship’s output, and “Fault management”. Further risk management measures are “Innovativeness”, “Prioritization”, “Protection of relationship related knowledge” and the amount of formal and informal “Communication”.

Figure 2 shows the results to the questions in each of the above mentioned categories and if they apply to the relationship at hand.

Findings

Cluster analysis shows that three groups can be distinguished. Relationships can be:

- Non-strategic, where replaceablity is high and for both partners the hold up risk is relatively low.

- Strategic, where both partners depend on each other.

- Asymmetric, i.e. one of the of the partner’s is dependent on the other but not vice-versa.

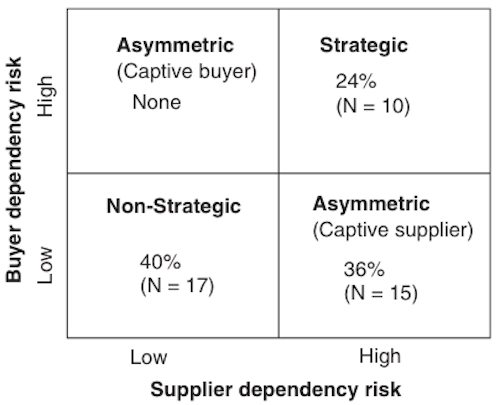

Figure 3 shows the possible combinations and the clustering framework suggested by the authors.

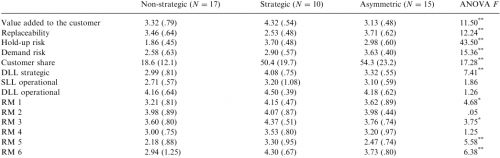

Figure 4 shows the results of the survey, when clustered.

The authors conclude:

- DLL Strategic (strategic double-loop learning) showed a significant difference across the clusters [and is highest with in the Strategic cluster]

- Both the protection of relationship-related knowledge (RM 5) and the amount of communication (RM 6) were exploited most in the strategic relationships

- [RM 1 and 3] (see figure 2) were widely used in strategic relationships and only moderately used in asymmetric and non-strategic relationships.

- Our study indicates that the risks and risk-management activities that suppliers perceive in their relationships are predominantly mutual with the customer.

- It could be concluded that the level of risk and dependency in supplier relationship has an effect on the exploitation of risk-management means.

Conclusion

To evaluate this paper one first has to analyze the methodology used. In this case a case study seems to be adequate for a topic where no further research exists, a reader of this article still has to keep in mind that the results are not representative for a population and, since only about 60% of the supplier’s of the OEM took part in the survey, the results may not even be representative for this company.

Furthermore I found there was too little overlap between the literature review and the survey. E.g. the risks discussed in the review were only partially reflected in the survey section.

On the other hand I think the framework can be used to distinguish and describe a large proportion of relationships and the findings above can be used as a guideline how to prioritize risk management efforts within each of these categories.

Hallikas, J., Puumalainen, K., Vesterinen, T., & Virolainen, V. (2005). Risk-based classification of supplier relationships Journal of Purchasing and Supply Management, 11 (2-3), 72-82 DOI: 10.1016/j.pursup.2005.10.005

Add new comment