Securing the Upstream Supply Chain

In this article the authors, Giunipero and Eltantawy (2004) explore situational factors which contribute to the company’s level of investment into risk management activities. These factors are:

- degree of product technology

- need for security

- importance of the supplier

- the purchasers’ prior experience

Risk Buffering and Risk Management

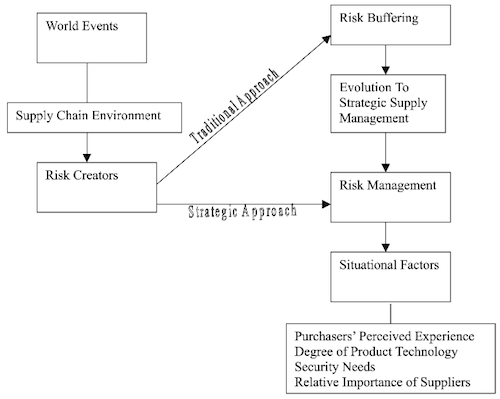

The authors argue that in literature and practice alike risk buffering activities are used too often instead of strategic risk management activities (see figure 1). Buffering strategies are those which are activated after the risk materializes. Examples are extra inventory or multiple suppliers.

But ultimately, long term stability can only be achieved by driving performance. So the goal should be to align risk management strategies and performance. Such could include purchasing practices as: industry consolidations, e-procurement, just in time deliveries.

Of course these strategies are likely to increase the risk of disruption at the same time.

Situational Risk Management

With this tradeoff in mind let’s think about what factors are important for the level of risk management? And how do these factors influence the level of investment?

From a literature study the authors concluded on the following propositions:

- Product Technology: High-tech markets require more extensive risk management than other low-tech markets with slower pace of technological changes.

- Security Needs: Those suppliers who provide items that have high security requirements require more extensive risk management than those providing items with relatively less security needs.

- Relative importance of suppliers: Major suppliers of high volume, value and/or critical items require more extensive risk management than those who supply fewer or less critical items.

- Purchasers’ prior experience: Suppliers with whom purchasers have less experience require more extensive risk management than those with whom there is a history of purchasing.

This propositions can be used for the rationalization of decisions on supply chain risk management, since

Supply professionals must have top management support. If a risk never materializes, it becomes very difficult to justify the time spent on risk assessments, contingency plans, and risk management

Conclusion

I think the last point is a very important one: Getting managements support for risk management investments. The propositions might seem to be only rule of thumb, but keep in mind that also any more sophisticated supply chain design method will be subject to scrutiny, and may lead to very similar results.

Giunipero, L., & Eltantawy, R. (2004). Securing the upstream supply chain: a risk management approach International Journal of Physical Distribution & Logistics Management, 34 (9), 698-713 DOI: 10.1108/09600030410567478

Add new comment