Stochastic Model for Risk Management

Defining a conceptual framework for supply chain risk management can support thinking about risks in supply chains and streamline the decision making process, and therefore improve the current supply chain at hand.

This is similar to a brown-field approach, where gradual changes and risk mitigation strategies are employed onto an existing supply chain. Thus another source for improvement strategies can be a green-field approach, where the supply chain is modeled and optimized to generate new input for real-world optimization.

Model

Goh, Lim and Meng (2007) develop a mathematical model for supply chain optimization. The goal is to optimize facility location and distribution logistics planing in an international setting.

Typically, the firm’s objective is to maximize its global after-tax profit subject to capacity constraints in each plant and demand requirements in each market. The firm thus needs to make an open/shut decision of plants together with the corresponding shipment quantities from such plants to targeted markets taking into account the attendant uncertainties in market demand, volatility in exchange rates, differing country tax rates, and varying import tariffs at different ports of call even within a country.

Solving the model

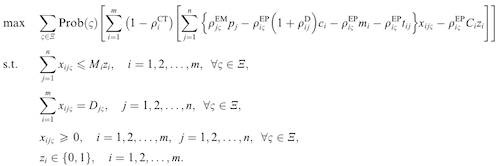

A major part of the model is its objective function, which is displayed in figure 1. In this case the random variables are demand, exchange rate, and import tariff.

Building on the Moreau–Yosida regularization the authors then develop a solution algorithm to solve the problem with profit maximization and risk minimization objectives.

Conclusion

It would be interesting to see this model applied to a real case, as well. But even if the authors presented a real world case there is still a huge gap in this area between the theoretical possibilities and the practical application. Mathematical models for supply chain management have been developed for decades but still mostly the operational models are applied in practice. One reason may be the inherent complexity of the model and the solution algorithms, another might be a managerial reluctance to rely with strategic decisions on models they do not understand. But what’s the alternative? Relying on a gut feel that is more reliable?

Goh, M., Lim, J.Y.S., & Meng, F. (2007). A stochastic model for risk management in global supply chain networks European Journal of Operational Research, 182 (1), 164-173 DOI: 10.1016/j.ejor.2006.08.028

Add new comment