Supply Chain Flexibility in an uncertain Environment: exploratory Findings from Five Case Studies

This is another look at flexibility strategies to reduce uncertainty in supply chains. This time from the point of view of five Chinese companies in the apparel industry.

Method

The authors use a case study to “illustrate and examine the different flexibility strategies adopted by supply chain participants as a result of different environmental uncertainties.”

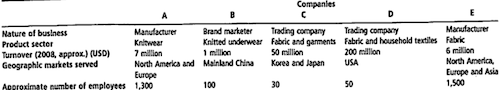

The five companies cover different parts of the apparel supply chain. A garment and a fabric manufacturer (companies A and E, respectively), two trading companies (C and D) and a brand company (B). This diverse sample should enable the authors to make more general deductions from the generated data.

Figure 1 shows some relevant background information for the companies.

Results

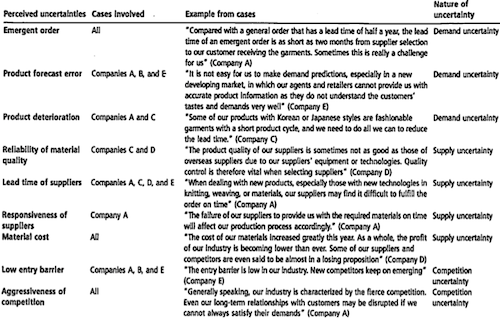

The first questions revolved around the perceived uncertainties experienced by the participants. All companies mentioned that emergent orders, uncertainties about material cost and the aggressiveness of the competition are perceived as major uncertainties (figure 2).

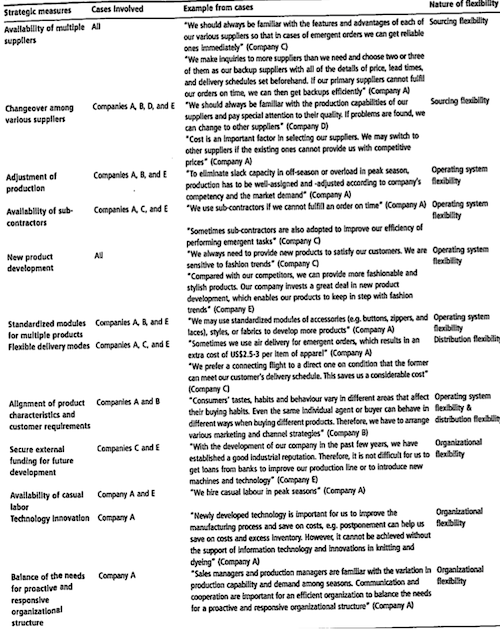

Several different supply chain strategies were employed, a summary is displayed in figure 3.

The authors especially wanted to highlight the influence of different environmental aspects on the chosen strategies. No pattern emerged when analyzing which flexibility strategies are used for which uncertainties.

So next the authors examined the impact of the general level of uncertainty experienced by the companies and compared it with the supply chain flexibility level chosen.

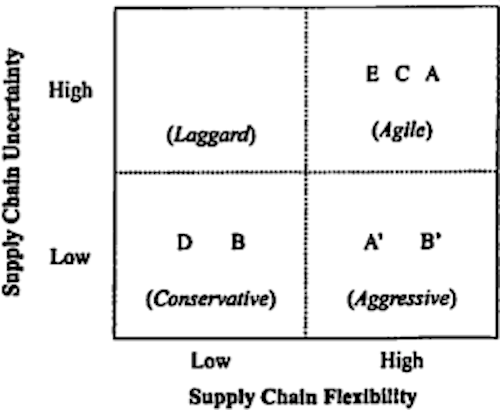

The authors came up with a matrix (figure 4). Where they contrast SC uncertainty and flexibility. Companies D and B find themselves in the conservative corner while E, C and A employ a high level of flexibility to combat the uncertainties. From the interviews the authors also deducted the future positions of the companies A and B, which are indicated as A’ and B’.

Next the authors discuss their findings and reach four conclusions:

- A low level of uncertainty in the supply chain leads to the adoption of a conservative flexibility strategy.

- A high level of uncertainty in the supply chain leads to the adoption of an agile flexibility strategy.

- An aggressive flexibility strategy can be proactively adopted through restructuring a firm’s operating system to reduce environmental uncertainties.

- An aggressive flexibility strategy can be proactively adopted through creating new opportunities to improve a firm’s supply chain flexibility.

Conclusion

I like case study research, since usually you can gain some really genuine and new insights, in this case: What are other companies doing to contain uncertainty and how are they employing flexibility for that?

In this case I liked the paper a lot as well… up to the matrix. I don’t like matrices where the axes are not independent, because that’s not how you generate a matrix. Take the Growth-Share-Matrix, where you have the axis market growth and market share. The one is dependent on the market and the other on one company’s share in it. Relation to one another: Independent.

Here we have uncertainty on one axis and a strategy to reduce uncertainty on the other. So of course most companies would lie somewhere in the middle. So there is not much to learn from it. Of course there is not a one-to-one relationship, but anyway.

I had several more points to complain (number of interviews also only five, conclusions drawn are directly linked to their flawed matrix-framework and no quantitative measures to assess the flexibility and uncertainty levels).

But I still think the strategies mentioned from the interviews are still worth considering when choosing your own strategies.

Yi, C.Y., Ngai, E.W.T., & Moon, K.-L. (2011). Supply chain flexibility in an uncertain environment: exploratory findings from five case studies Supply Chain Management: An International Journal, 16 (4), 271-283

Add new comment