Supply Chain Network Design

What is supply chain network design? Where does the “design” come into play? I recently read the book “Supply Chain and Logistics in National, International and Governmental Environment” by Zanjirani Farahani, Asgari, Davarzani (Eds.) (you can find more information on the publishers web site and buy it online at amazon.com), from which I present you today one of the chapters, which is on supply network design.

Supply Chain Design Questions

The authors start with the questions which have to be answered within the supply chain design domain, like

- Which producers should we use?

- How many DCs should there be and where should they be located?

- How do we set the DC capacity at each location?

- What products should each factory produce?

Network Design Problems

For solving those problems mentioned above, it is convenient to use a model of your supply chain, so you would be able to test different configurations or use optimization methods to find the perfect configuration.

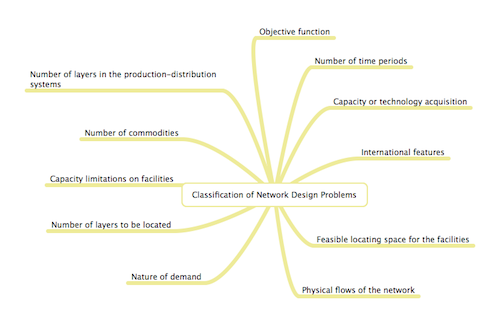

So, the next step is to build a model of the supply chain. Davarzani and Rezapour give a comprehensive listing of the items you have to pay attention to while building the model.

Some of the major points are the objective function (cost oriented, profit oriented or service oriented), the number of layers you have to locate (do you have the ability to influence the location of your customers or suppliers?). Furthermore you have to answer questions on the demand (stochastic, deterministic) and international features of the network.

Network Design Models

As soon as you have answered these questions for your supply chain Davarzani and Rezapour give you a choice of different, current mathematical models which can be used for your needs. Here I can only give a short description of the models proposed:

- Basic Model

three-tiered supply chain system with one or more suppliers, DCs and retailers

- Capacitated DC

additional assumption that DCs have capacity restrictions

- Service Considerations

inclusion of a service level within the objective function

- Parameter Uncertainty

allowing parameters to be described by discrete scenarios (with probability of occurrence)

- Closed-loop Network Design

inclusion of reverse logistics - International Distribution Network Design

activities and sourcing decisions can be adapted to countries conditions

Conclusion

After reading this chapter I was exited to get such a concise overview over the current (2009) state of supply chain network design. But after more careful considerations I am somewhat disappointed, first, from the state of the art itself: You still can find the basic model in it, a model which in a little bit more simplistic form has already been taught at the university, if you have a look at the first extensions: eg. capacitated distribution centers, you have a direct look at the limitations of the model before. Well I have never seen a supply chain without capacity constraints, have you?

Second, modeling in general is the process of abstraction of the real world, so the mentioned limitations are a natural cause of this. But sadly research on the effects of decisions which have been taken due to these restricted models are rare, so you as the decision maker always have the risk of choosing the wrong (eg. too much aggregated) model. This is known as model risk, and sadly this risk is only seldomly taken into account in supply chain management. To be honest I have not found a single article about it.

Third, to alleviate some of the restrictions other methods (than mathematical programming) can be used. My favorite would be supply chain simulation. Of course, you still have abstraction, but if the designer decides on lifting some of them (eg. have a different distribution of demand, …) this can usually be done much easier than with a mathematical model. Of course you usually also loose the ability to have optimal recommendations, since optimization of such a model takes a lot of CPU power.

Davarzani, H. and Rezapour, S. (2009). Supply Network Design in Supply Chain and Logistics in National, International and Governmental Environment, Zanjirani Farahani, R.; Asgari, N.; Davarzani, H. (Eds.), Springer-Verlag, April 2009.

Add new comment