Supply Chain Simulation and the Bullwhip Effect

I already reviewed some articles by Denis Towill primarily because he does some interesting research on simulation and supply chains, but also because I like his clear style in his articles.

In one of his early papers (1992) he teamed up with Naim and Wikner and described state of the art strategies to fight the bullwhip effect or as it is called in the paper by its older name: Industrial Dynamics.

Industrial Dynamics

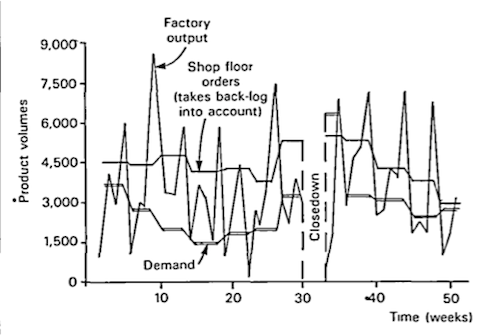

I already described the causes of the bullwhip effect and how to measure it in an older post. The bullwhip effect describes amplifications in demand within the supply chain. Exemplary effects can be seen in figure 1.

Improving SC Dynamics

One way to improve the supply chain dynamics is to introduce a leaner supply chain, which in turn will lead to lower lead times and lower amplifications.

In a lean supply chain stocks are located at a low level of “added value”, to keep the inventory cost lower.

The next decision to make is to find the right trade-off between stock levels and production rates. If you increase the flexibility of production, you might be able to reduce the inventory overall. There are two alternatives:

- Fixed process rate / varying inventory levels

- Varying process rate / fixed inventory

There are four sectors where where further improvements can be acchieved:

- Industrial engineering improvements, eg. changing the product design or changing the layout of the production

- Production engineering improvements, eg. integration and sequencing of processes to reduce lead times

- Information technology improvements, eg. quicker data capture and electronic data interfaces

- Operations engineering improvements, eg. pull system instead of push, shared planning

Optimization

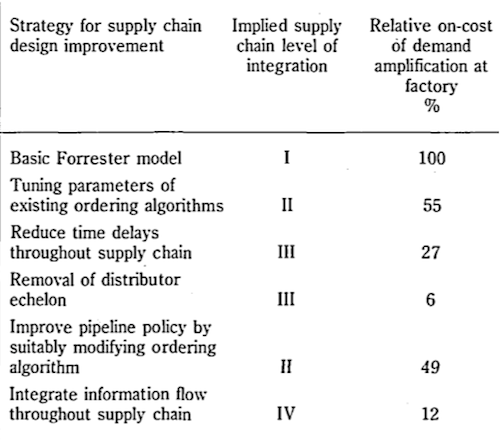

To examine their points, Towill et al. design a simple supply chain simulation model with four stages (retailer, distributor, warehouse and factory). The results (figure 2) show that above mentioned improvements can lead to a reduction in the amplification.

The authors conclude that reducing the overall lead times in the supply chain may be an expensive solution. As an alternative they suggest to remove some stages from the chain which also leads to significant reductions in the amplifications. Probably the cheapest way to reduce the bullwhip effect may be to increase collaboration in the chain, in this case especially concerning forecasts and planning.

Conclusion

Simulation model cannot only help in theoretical exercises. There are very important applications in real life applications as well when the task is to optimize generic strategy recommendations like those mentioned above.

Towill, D., Naim, M., & Wikner, J. (1992). Industrial Dynamics Simulation Models in the Design of Supply Chains International Journal of Physical Distribution & Logistics Management, 22 (5), 3-13 DOI: 10.1108/09600039210016995

Add new comment