The Impact of Supply Chain Integration on Performance

An ongoing debate in supply chain management is about the degree to which companies should collaborate with their supply chain partners. In business and research the concept is called supply chain integration and may also be a useful strategy for reducing certain risks. And of course it is an often used strategy in supply chain management in general

Analyzing the effect of supply chain integration on performance therefore is an important issue in SCM research.

Supply Chain Integration

In the case of this study supply chain integration (SCI) can be defined as

the degree to which a manufacturer strategically collaborates with its supply chain partners and collaboratively manages intra- and inter-organization processes. The goal is to achieve effective and efficient flows of products and services, information, money and decisions, to provide maximum value to the customer at low cost and high speed.

The authors split SCI in three dimensions: customer, supplier and internal integration.

Internal integration and external integration play different roles in the context of SCI. While internal integration recognizes that the departments and functions within a manufacturer should function as part of an integrated process, external integration recognizes the importance of establishing close, interactive relationships with customers and suppliers.

Methodology

The paper employs a survey design. Participants of the survey were manufacturing companies based in China.

Because of China’s size and economic diversity, we strategically selected five cities representing different stages of economic development.

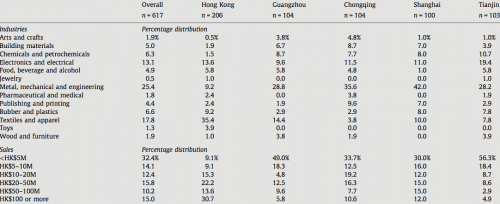

Overall 4569 companies were contacted, 1356 questionnaires were distributed with a result of 617 usable replies.

Figure 1 shows profiles of the responding companies.

The authors suggest the following hypothesis.

- H1a. Internal integration is positively related to the operational performance of the manufacturer within a supply chain.

- H1b. Internal integration is positively related to the business performance of the manufacturer within a supply chain.

- H2a. Customer and supplier integration are positively related to the operational performance of the manufacturer within a supply chain, given the relationship between internal integration and operational performance.

- H2b. Customer and supplier integration are positively related to the business performance of the manufacturer within a supply chain, given the relationship between internal integration and business performance.

- H3a. Customer and supplier integration will moderate the relationship between internal integration and operational performance.

- H3b. Customer and supplier integration will moderate the relationship between internal integration and business performance.

- H4. An emergent taxonomy of manufacturers can be developed, based on their patterns of supplier, internal and customer integration.

- H5a. The patterns of SCI are related to the operational performance of the manufacturer within a supply chain.

- H5b. The patterns of SCI are related to the business performance of the manufacturer within a supply chain.

Results

The analysis of the survey offers several interesting results, these are the main points:

- We found that most of our hypotheses were supported or partially supported, broadly indicating that SCI is related to performance.

- Internal integration was directly related to both business and operational performance and that customer integration was directly related to operational performance.

- Although supplier integration was not directly related to either type of performance, the interaction of supplier and customer integration was related to operational performance.

- Our findings indicate that supplier integration is important to performance, but in a different way than internal and customer integration are.

- Since the objective of SCI is to provide maximum value to the customer, the measurement of operational performance is necessarily customer-oriented.

- Overall, the contingency approach reveals that internal integration forms the foundation upon which customer and supplier integration build. This suggests that companies should begin SCI with internal integration, laying the foundation for customer and supplier integration.

- The configuration approach showed that the overall SCI construct was related to both operational and business performance.

- The configuration approach also reveals that the effect of SCI is cumulative, providing significant insight for companies in implementing it.

Conclusion

The study shows that all three dimensions of supply chain integration are important for the performance of a manufacturing firm across industries. And China as the modern manufacturing hub is a great place to do research on this topic.

Flynn, B., Huo, B., & Zhao, X. (2010). The impact of supply chain integration on performance: A contingency and configuration approach Journal of Operations Management, 28 (1), 58-71 DOI: 10.1016/j.jom.2009.06.001

Add new comment