The Supply Chain Flexibility Concept

Today’s article finally closes a gap in the blog that I wanted to close for a while now.

Flexibility can be seen as a key basis for some companies and supply chains as a business strategy and for most companies as an approach for risk mitigation. The article by Duclos et al. presents a flexibility concept from a supply chain point of view and can be used as a foundation for further decisions on the supply chain strategy.

Methods and literature

The authors stand on the shoulders of giants and therefore start by presenting existing classification schemes and flexibility typologies. The authors locate the trend to integrate more responsive manufacturing strategies in the 1970s, when companies realized, that

they could no longer maintain the large volumes of production and cost efficiency of their production processes with these higher levels of change and uncertainty.

Later in the 90s supply chain management emerged with the goal to integrate suppliers and customers within the strategies as well. But the roots of flexibility still can be found in the early manufacturing optimizations.

In general flexibility can be seen as a multi dimensional construct, but the number and content of these is more than controversial. Some of them are:

- Machine flexibility

- Material handling

- Volume flexibility

- Process flexibility

- …

But there are more aspects to flexibility, since it can be argued that it cannot be enough to establish flexible processes, but flexible organizations.

So the goal should be strategic flexibility, which can be described by:

1) Resource flexibility: the extent to which a resource can be applied to a range of alternative uses, the costs and difficulties associated with the switching from one resource to another, and the time required for the switch.

2) Coordination flexibility: flexibility in those processes that redefine product strategies, reconfigure chain of resources to produce product, and re-deploy those resources needed to produce the product.

Supply chain flexibility

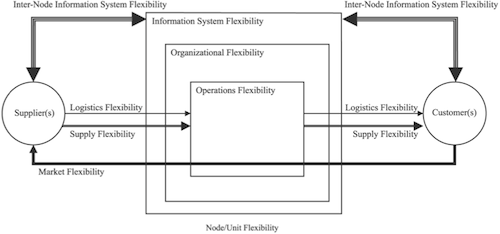

Based on these considerations the authors develop their model for supply chain related flexibility (figure 1).

It consists of six core units of flexibility which aggregate and extend the existing concepts.

1) Operations system flexibility (both manufacturing and service): ability to configure assets and operations to react to emerging customer trends (product changes, volume, mix) at each node of the supply chain.

2) Market flexibility: ability to mass customize and build close relationships with customers, including designing and modifying new and existing products.

3) Logistics flexibility: ability to cost effectively receive and deliver product as sources of supply and customers change (customer location changes, globalization, postponement).

4) Supply flexibility: ability to reconfigure the supply chain, altering the supply of product in line with customer demand.

5) Organizational flexibility: the ability to align labor force skills to the needs of the supply chain to meet customer service/demand requirements.

6) Information systems flexibility: the ability to align information system architectures and systems with the changing information needs of the organization as it responds to changing customer demand.

Conclusion

The authors conclude with the following argument: If competition is shifting from a firm-to-firm basis to a chain-to-chain competition, also the concepts like flexibility necessarily have to be adjusted towards a supply chain view. So in a supply chain context, the flexibility of one company can only be part of a larger supply chain flexibility strategy.

And I totally agree here. What do you think?

Duclos, L., Vokurka, R., & Lummus, R. (2003). A conceptual model of supply chain flexibility Industrial Management & Data Systems, 103 (6), 446-456 DOI: 10.1108/02635570310480015

Add new comment