Design of Agile Supply Chains

I already reviewed two other articles about agile supply chains. One on the role of distribution centers in supply chains and one on the migration from lean to agile supply chains.

But the question comes to mind if lean and agile supply chains have to be mutually exclusive or if it is possible to combine them. Christopher and Towill (2001) had a look at this question regarding the supply chain design.

Factors for Leanness / Agility

Several factors influence the design decision if a supply chain should be more agile or lean. Nowadays more often than not supply chains compete, not companies. This implies that not only companies must act market orient, but also supply chains.

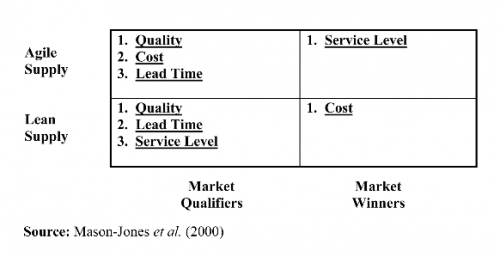

Market orientation can be analyzed using the market winner / market qualifier concept. This also means that there are different foci of the lean and agile supply chain.

Strategies

Christopher and Towill mention three ways to combine the lean and agile paradigm in one supply chain:

- 80/20 approach

Usually in a supply chain with multiple products only a few of them make most of the overall volume (20% make 80% of the volume). Result: for the high volume products choose a lean approach, while for the low volume products an agile strategy might be better suited. - Decoupling point approach

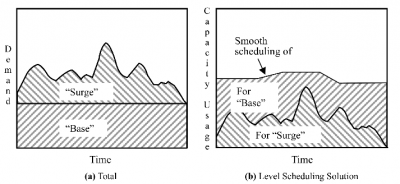

Strategic inventory can act as a decoupling point within a supply chain. If you select this point wisely, it can be beneficial to use a lean strategy up to this point and an agile strategy after this point. - Base and surge demand

the strategies can also be combined if the demand pattern shows a base demand. This demand could be produced using a lean strategy, while the surge implements a more agile approach.

Conclusion

It is important to see, that not only leanness and agility can be combined, but also the strategies mentioned above can be used complementarily.

Christopher, M., & Towill, D. (2001). An integrated model for the design of agile supply chains International Journal of Physical Distribution & Logistics Management, 31 (4), 235-246 DOI: 10.1108/09600030110394914

Add new comment