Measuring agile Capabilities in the Supply Chain

Today I introduce you to the process of measuring agility in a supply chain. Agility is a major concept in the research of the last 10 years or so. I already have written some articles on this topic:

- Design of Agile Supply Chains

- Distribution Centers in Agile Supply Chain Design

- Agile Supply Chains

- Foundation for a Responsive Supply Chain

Consequently, the goal of today’s article is to expand on those and define what are the key factors of SC agility and how it could be measured.

Method

The paper presented is based on two sources: an empirical investigation of agile capabilities in Europe and a literature review of the current research available.

The concept developed is based on the literature review and it is then tested using the survey.

Agility Framework

Agility has already been described early in four basic dimensions (according to Goldman et al.,1995): 1) Enriching the customer, 2) cooperating to enhance competitiveness, 3) organizing to master change and uncertainty, 4) leveraging the impact of people and information

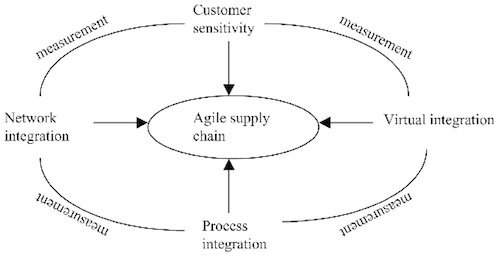

An extensive literature review leads to the agility framework shown in figure 1. The dimensions are described below (quoted).

- Customer sensitivity

Customer centred versus product centred logistics policies (ten questions): assumes that “agile” policies emphasize customers and markets, while “lean” policies focus on the elimination of waste in products and processes. - Virtual integration

Immediate conversion of demand information into new products using knowledge-based methods versus multi-stage, multi-function methods (three questions): assumes that agile policies focus on instantaneous demand capture, interpretation and response while lean policies emphasize stable production periods and protecting the “operations core”. - Process integration

Self management versus work standardization (five questions): assumes that agile policies focus on operator self- management to maximize autonomy and immediate response, while lean policies emphasize work standardization to ensure conformance to quality and productivity standards. - Network integration

Fluid clusters v. long term supply chain partnerships (six questions): assumes that “agile” policies emphasize fluid clusters of network associates, while lean policies focus on a more fixed set of long-term stable partnerships. - Measurement

Capabilities versus “world class” measures of performance (seven questions): assumes that agile policies are based on broad-based measures that underpin capabilities, while lean policies emphasize “hard” measures such as quality and productivity only.

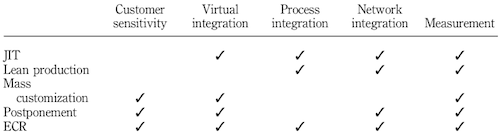

The authors go further and analyze how these dimensions are represented other common supply chain concepts like just in time or lean production (figure 2).

Changed Approach

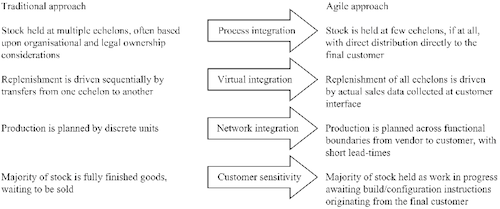

The “agile approach” changes supply chain management as a whole. The authors compare the traditional vs. agile approach very extensively. A summary can be found in figure 3.

Conclusion

Overall this article is a good starting point to answer the question “what is agility?”. For business it is important to transfer this framework into their measurement systems to get a benchmark how well they perform, since “you cannot manage what you don’t measure”.

Hoek, R., Harrison, A., & Christopher, M. (2001). Measuring agile capabilities in the supply chain International Journal of Operations & Production Management, 21 ½, 126-148 DOI: 10.1108/01443570110358495

Comments

Thanks for sharing such a great idea.

Add new comment