Measuring Supply Chain Performance

Last week I conducted another Interview for the empirical part of my research. And we also discussed how to measure performance within the SC. As it turns out, multiple measures, namely service, cost, working capital are used. Sadly in literature many authors still focus on a single measure only and I wanted to know more about it. So I read an article by B. Beamon (Measuring Supply Chain Performance) to get an overview over performance measures used and how to select the right one(s).

History of Supply Chain Performance Measures

Supply chains consist of many different companies and within those, various functions. So first measures have relied on characterizing individual systems like production, distribution, or inventory management. In literature the measures have often been categorized into aspects of quality, time, flexibility, and cost.

But most often cost is used as an only measure or cost and another measure for customer responsiveness is applied. Other more qualitative measures, like customer satisfaction or concerning risk management, are seldom used due to their restricted applicability in quantitative models.

Measures are generally thought of being effective if the following characteristics are fulfilled:

- inclusiveness (measurement of all pertinent aspects)

- universality (allow for comparison under various operating conditions)

- measurability (data required are measurable) and

- consistency (measures consistent with organization goals)

Performance Management System

The last bullet point highlights another topic: It is also important not only to focus on the measures used, but also to reflect on the performance measurement system as a whole. Especially, it is important to consider the effects of a specific corporate strategy on the performance measures used. Thus there are several caveats when evaluating options for performance measures:

- If using only one performance measure make sure that it can adequately describe the performance of the system in focus.

- When using cost as (only) measure, be careful to include all necessary costs in the calculation. Pitfalls include cost of obsolescence or rework due to engineering changes

- Align performance measures with the strategic goals

Framework

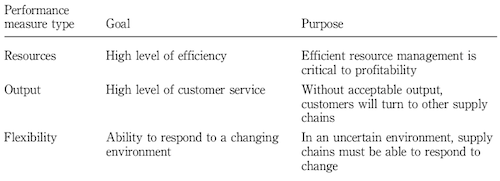

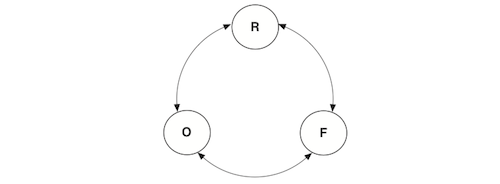

Individual performance measures are usually non-inclusive so the goal for a performance management system should be to include more aspects. Beamon suggest to focus on measures for resources ®, output (O) and flexibility (F) (see figure 1 and 2).

Examples for resource measures are: total cost, distribution cost, inventory cost.

Output can be measured quantitatively as number of items produced or number of on-time deliveries or profit; alternatively qualitative measures like customer satisfaction or quality can be used.

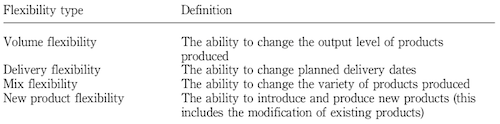

Flexibility is harder to measure, Beamon details on a quantitative approach for measuring it, focussing on volume, delivery, mix and new product flexibility.

Conclusion

The use of simple performance measures is tempting, since simple measures are more easily implemented into numerical models; however, by limiting the scope of the performance measurement, these models ignore important performance trade- offs.So it is obviously important to focus on meaningful measures. While reading the article I didn’t quite understand the authors relation to profit as a performance measure. Return on Investment for example is listed under the category cost-measures, profit itself is listed under output. Neither is really correct if you define profit as revenue minus cost since, profit affects both sides, resources and output.

Beamon, B. (1999). Measuring supply chain performance International Journal of Operations & Production Management, 19 (3), 275-292 DOI: 10.1108/01443579910249714

Add new comment