Strategic Supply Chain Design and the Product-Relationship Matrix

Yet another case study. This time on strategic network design. Why? A major problem for businesses is to find the right strategy for a given situation. And “right” here means optimal (for a given KPI).

Research question might be: Are there general categories which can be used to make different decision situations comparable? And if yes, what would optimal strategies under these circumstances be?

Definitions

Seuring (2009) tries to answer the first research question using case studies. From literature he defines the strategic decision fields to be

- Product design/engineering (products or parts),

- Plant and equipment (plant),

- Organisation and management (processes),

- Labour and staffing (people) and

- Production planning and control (planning).

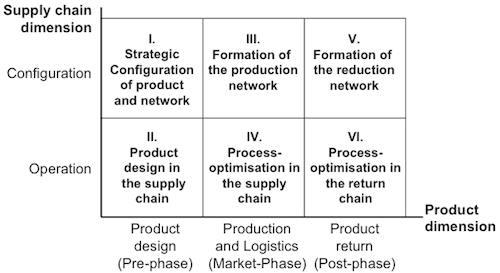

For Seuring the SC decisions best can be categorized using a two dimensional matrix with the supply chain at the y-axis and the product dimension on the x-axis. As you can see in figure 1 he does not focus on the supply / demand side (like eg. Fisher 1997), but in both dimension aims at the process view.

The supply chain dimension with can be divided into configuration and operation, the product dimension into the product design, production and return phase.

Advantages

Overall this framework shows a sequential view on the strategic decisions in a supply chain. But it also supports dynamic adaptations to differing origins, eg: A redesigned product within an existing supply chain would only make the steps II (Product design) and IV (Process optimization) necessary; changes to the network, like adding a new supplier, would concern square III (Formation of production network).

Cases

Using five different cases Seuring goes through the above mentioned strategic decision categories. The cross-case analysis reveals that the categories may sometimes be overlapping (production and return phase), but the decision can still be sorted into one or the other category.

Conclusion

As described in the introduction, the next step would be to use these categories to find general, optimal strategies which should be followed in each of the parts of the matrix in figure 1.

But while I was reading the paper I realized that this might not be possible, since the steps are to vague for that.

Hence, the framework offers an alternative approach, which not only takes a look at the content of the decision, but also adds a process perspec- tive. Such a more dynamic approach allows structuring the related decision based on the relationship and the product life-cycle dimension.

So my question, how can you use this framework beside finding optimal solutions for network design problems?

One suggestion might be, to use the process nature of the framework and analyze the organizational relationships while going through the different decision phases.

What do you think?

Seuring, S. (2009). The product-relationship-matrix as framework for strategic supply chain design based on operations theory International Journal of Production Economics, 120 (1), 221-232 DOI: 10.1016/j.ijpe.2008.07.021

Add new comment