The Supply Chain Uncertainty Circle

How to shrink the “Uncertainty Circle” is the topic of a paper I read today. It has been written by Rachel Mason-Jones and Denis R. Towill and can be downloaded here free of charge.

This article from 1998 focusses on how to shrink the uncertainty within a supply chain and therefore improve performance, since

we believe that those companies which cope best withuncertainty, are most likely to produce internationally

competitive bottom-line performance.

This hypothesis is also backed by several other authors like, Craighead et al. (2009) or Hendricks and Singhal (2005).

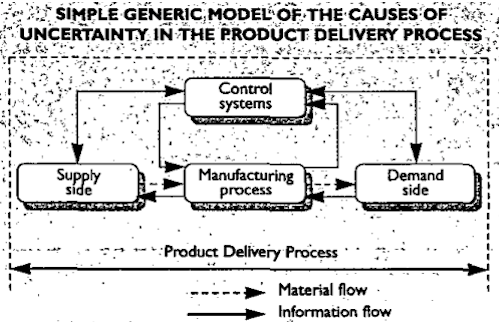

Within the product delivery process for a single company, the authors find four causes of uncertainty: supply side, manufacturing processes, control systems and demand side (see figure 1).

The Circle

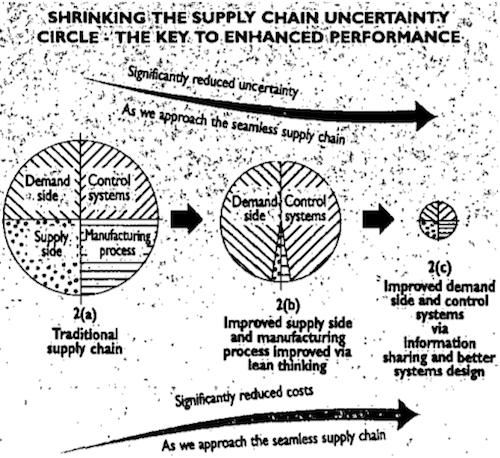

With the Uncertainty Circle it is now possible to visualize to effect of shrinking one of the risks without the other: Overall risk is only reduced by a (comparatively) small amount. This furthermore implies the goal for supply chain risk managers: Reduction of risk on all frontiers!

The authors then argue that much potential is left untouched on the reduction of demand side uncertainties and control systems.

Demand side risks can be reduced by improving the information flow from the end-customer throughout the supply chain and companies can tackle control risks by improving their ability to act on this new information with a adequate Decision Support System.

Supply Chain Design Strategies

The authors then simulate a given supply chain and test strategies to improve (in figure 3) “Information pipeline time compression only”, “Material flow pipeline compression only”, “Total Cycle Time compression”.

Conclusion

Even though the article has been published twelve years ago the concept of the Uncertainty Circle can still be used as a framework to reduce risks within a supply chain. The comparison table shows the effects of different risk mitigation strategies clearly and should adapted and used by more companies.

Mason-Jones, Rachel, & Towill, Denis R. (1998). Shrinking the Supply Chain Uncertainty Circle IOM Control, 24 (7), 17-22

Craighead, C., Hult, G., & Ketchen Jr., D. (2009). The effects of innovation–cost strategy, knowledge, and action in the supply chain on firm performance Journal of Operations Management, 27 (5), 405-421 DOI: 10.1016/j.jom.2009.01.002

Hendricks, K., & Singhal, V. (2005). An empirical analysis of the effect of supply chain disruptions on long-run stock price performance and equity risk of the firm Production and Operations Managment, 14 (1), 35-52

Add new comment